Training and onboarding on the shop floor refer to the structured processes of preparing new or existing employees to perform production tasks safely, efficiently, and accurately.

Both processes often combine theoretical instruction (e.g., safety or quality principles) with hands-on practice at the workstation to ensure workers can apply what they learn directly in their daily tasks.

Manufacturers face several challenges when it comes to effectively training, onboarding, and upskilling shop floor workers, many of which directly impact productivity, quality, and employee retention:

Training-on-the-job

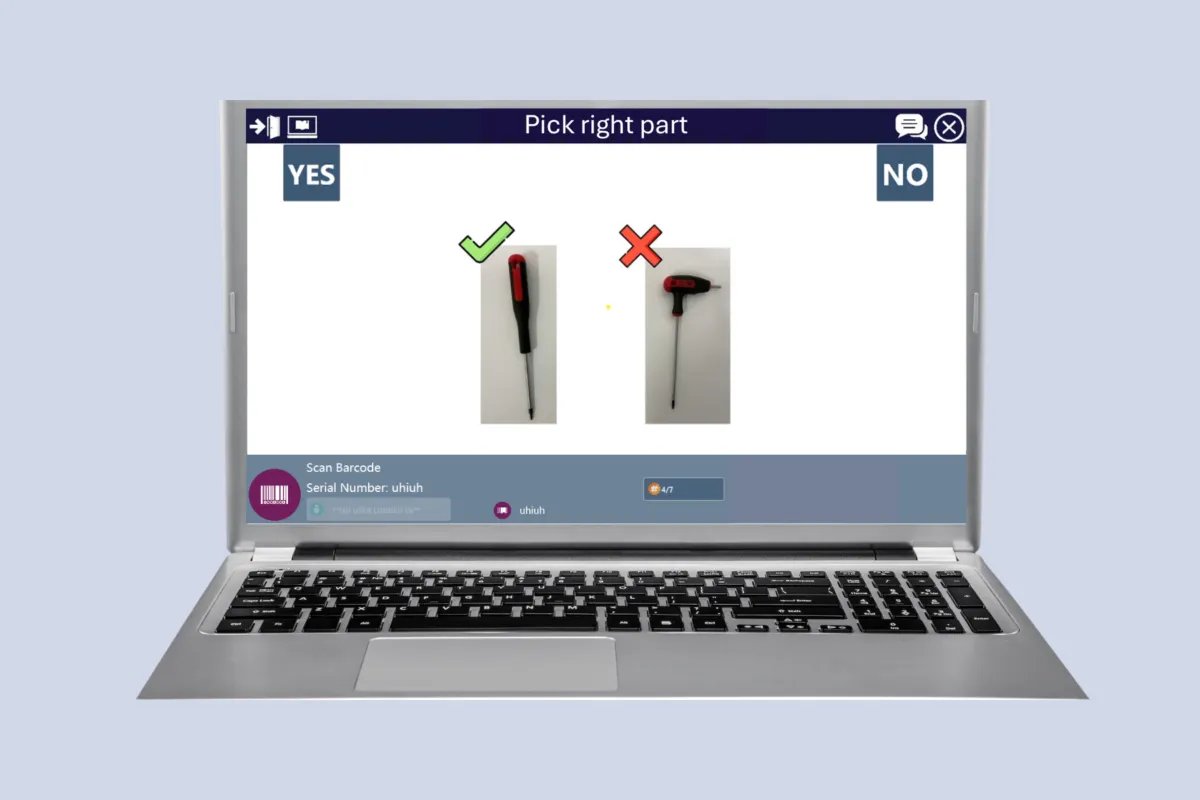

Convert paper-based manuals into digital instructions

Projected visual cues onto the work area

Progress to the next process step automatically

Display personalized instructions adopted to operator’s skill level

Digital work instructions (DWIs) are electronic versions of traditional paper-based manuals that guide operators step-by-step through assembly or operational tasks using digital devices such as PCs, tablets, or smartphones.

Advantages

Considerations

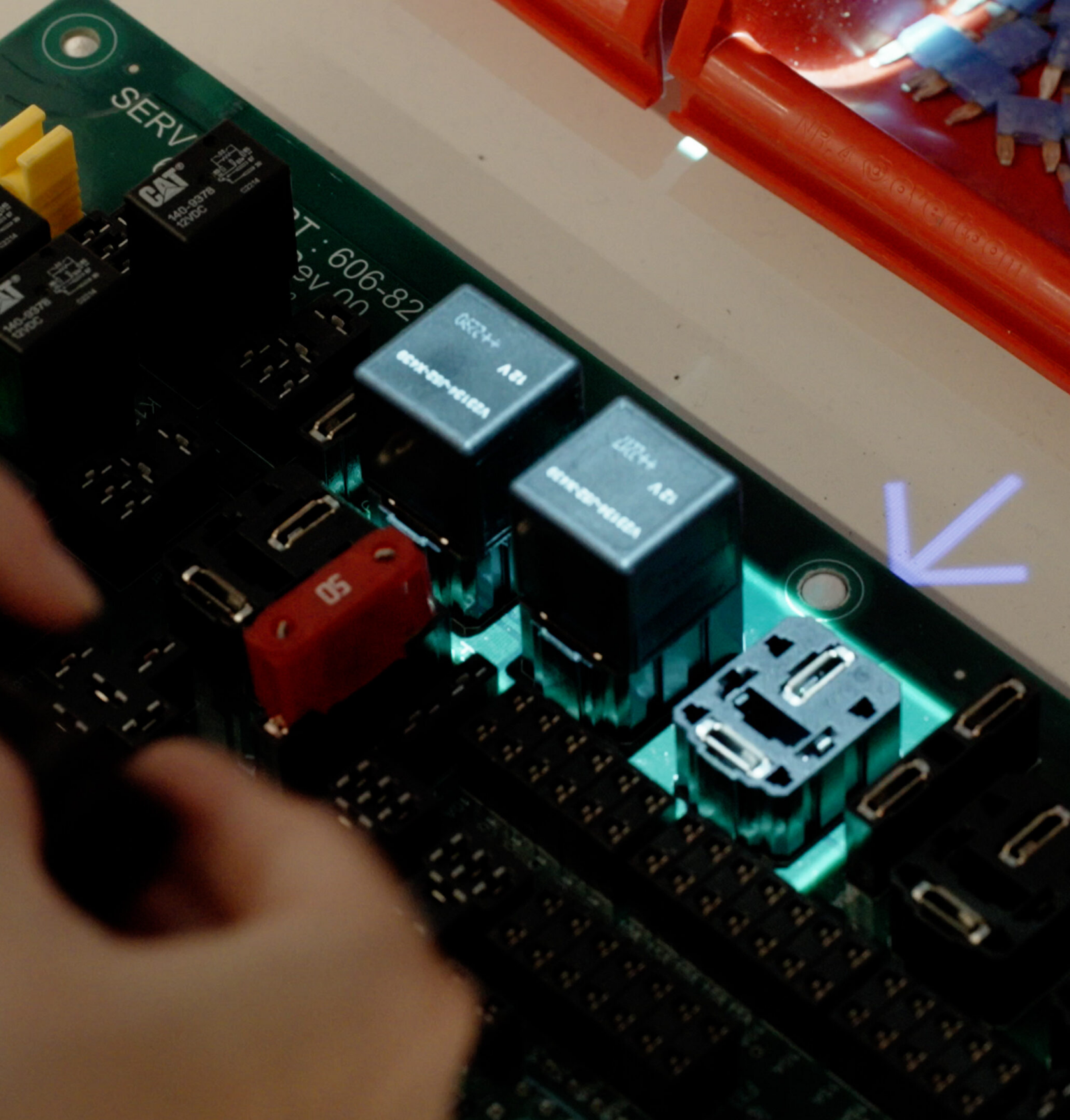

Projection-based augmented reality (AR) is a technology that uses a standard projector to display digital information, such as text, images, or visual cues, directly onto a physical surface or workspace, rather than showing it on a separate screen.

Advantages

Considerations

Sensors are a powerful way to automate process confirmation on the shop floor. Instead of requiring operators to manually click a button after each step, sensors can automatically detect when an action has been completed. This enables hands-free operation and smoother training, allowing operators to progress through tasks seamlessly and efficiently.

Advantages

Considerations

Competence-based work instructions take into account the competence and experience level of each operator.

Our operator guidance solution enables the display of fully customized instructions based on a worker’s skill level, experience, and language preference.

Advantages

Considerations