With conventional direct-drive DC tools, operators must absorb significant reaction forces, approximately ±7 Nm for pistol nut runners and up to ±40 Nm for angle nut runners. Beyond these limits, expensive and bulky torque arms or manipulators are required to safely manage the load. For many applications above 50 Nm, direct-drive tools simply generate too much reaction torque to be handled comfortably or safely. Because operator health and safety are critical, pulse fastening tools offer a far superior alternative.

Traditional DC tools apply torque in one continuous motion. When the fastener reaches its target torque, the sudden stop transfers a high counterforce directly to the operator’s wrist and arm. This is why torque arms and manipulators are often required for higher torque applications.

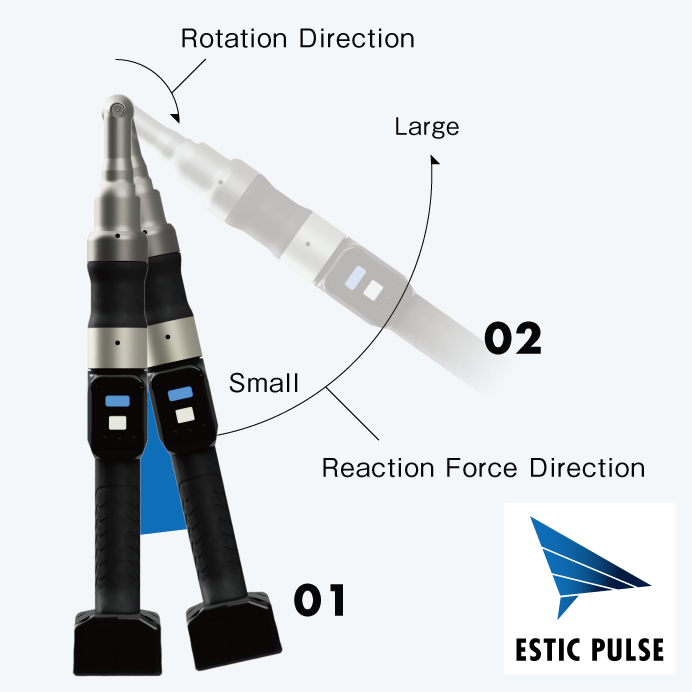

Pulse fastening technology works differently.

Instead of applying constant torque, the motor delivers a series of rapid micro-impulses. Each pulse tightens the fastener incrementally and then briefly releases the reaction force before the next pulse. This pulsed tightening cycle prevents torque buildup and dramatically reduces the force transmitted back to the operator, delivering a smoother, safer, and more ergonomic fastening experience.

Torque is delivered in controlled bursts, releasing stress between pulses. This minimizes counter-torque and protects the operator’s wrist and arm.

Lower reaction forces reduce fatigue and the risk of musculoskeletal injuries. In many cases, pulse tools can even be safely operated with one hand.

The reduced reaction torque often eliminates the need for bulky support equipment, saving space, installation time, and maintenance costs.

Without reaction arms, operators move faster, work in confined areas more easily, and achieve shorter cycle times.

Despite the intermittent tightening method, pulse tools maintain torque precision comparable to direct-drive systems.

Fewer accessories, less maintenance, higher throughput, and improved ergonomics all combine to reduce overall system cost.

| Feature | Direct Drive DC Tools | Pulse DC Tools |

| Torque application | Continuous, smooth rotation | Short, controlled torque pulses (intermittent) |

| Reaction force on operator | High, full torque is transmitted back to the user | Very low - torque is released between pulses |

| Operator fatigue | High, especially at higher torque levels | ⬇️Significantly reduced |

| Risk of injury | Higher risk of wrist and arm strain | ⬇️Much lower risk due to minimal counter-torque |

| Torque arms / manipulators | Often required above ~7 Nm (pistol) and ~40 Nm (angle) | ⬇️Often not required, even at higher torque |

| Ergonomics | Heavier setups due to stabilizers | ⬇️Lighter, more compact, sometimes one-hand operable |

| Accuracy & repeatability | Stop when torque is right | ⬆️Stop when bolt is actually stretched correctly -> clamping force accurate! |

| Installation cost | Higher - requires torque arms, fixtures, maintenance | ⬇️Lower - fewer mechanical accessories |

| Noise level | Generally quieter | ⬆️Can be slightly louder due to pulsing |

| Setup time | Can be used on different joints | ⬆️Need to be adjusted per joint |

| Maintenance | Higher, because of high mechanical stress | ⬇️Low maintenance |

| Lifetime cost | Higher | ⬇️Lower |

In reality, the opposite is true: it is not torque that holds a joint together but clamping force, and torque is only an indirect indicator of that force. The real objective is correct bolt stretch, which equals correct clamping force, and pulse tools achieve this by tightening in tiny elastic loading cycles. Because the system measures joint elasticity, dynamically adjusts pulse energy, and stops based on the actual response of the joint rather than a static torque value, it dramatically reduces the ±50% variation in clamping force that can occur when two bolts are tightened to the same torque.

In simple terms, direct-drive tools stop when torque “looks right,” while pulse tools stop when the bolt is truly stretched correctly, making them not just torque-accurate, but clamping-force accurate.

| Cable Pulse Tools | Battery Pulse Tools | |||||

| STANLEY | ESTIC | YOKOTA | STANLEY | ESTIC | YOKOTA | |

| Brand |  |  |  |  |

|  |

| Model |  |  |  |  |  |  |

| Tool Name | EPB series | EH2 series | E-Wrench | QB Series | EHC2 series | Cordless System Wrench |

| Covering Range | 0,6…150Nm | 1…180Nm | 3…90Nm | 1…14Nm | 1…100Nm | 5…80Nm |

| Versions | Pistol, Angle | Pistol, Angle | Pistol | Pistol, Angle | Pistol, Angle | Pistol |

| Number of presets | 256 | 99 | 16 | 256 | 99 | 16 |

| Drive | Transducerized Pulsing | Transducerized Pulsing | Transducerized Pulsing | Transducerized Pulsing | Transducerized Pulsing | Transducerized Pulsing |

| Reaction device needed? | no | no | no | no | no | no |

| Monitoring | Torque & Angle data | Torque & Angle data | Torque & Angle data | Torque & Angle data | Torque & Angle data | Torque & Angle data |

| Communication | Open Protocol, Fieldbus, Toolsnet | Open Protocol, Fieldbus, Toolsnet | Open Protocol | Open Protocol, Fieldbus, Toolsnet | Open Protocol, Fieldbus, Toolsnet | Open Protocol |

| Controller Name | SC series | HT45/50 series | YETC series | SC series | EHC2-MIFseries | YS-Z series |

|  |  |  |  |  | |

| Controller capacity | 1 tool/controller | 1 tool/controller | 1 tool/controller | 6 tools/controller | 10 wireless tools/controller | 4 tools/controller |