In modern manufacturing, fasteners are no longer tightened by feel alone. Electric screwdrivers and electric nutrunners both use motor-driven torque to deliver consistent results, but they are designed for very different levels of precision, power, and process control. Choosing the right tool is critical for ensuring product quality, operator efficiency, and full process reliability. This guide explains the key differences and helps you determine when a lightweight electric screwdriver is sufficient, and when a high-performance electric nutrunner is essential.

Both electric screwdrivers and electric nutrunners use an internal motor to automatically generate torque, offering far greater speed and consistency than manual tightening tools. They are essential in modern production environments where process reliability, repeatability, and documentation are critical.

The key distinction is simple:

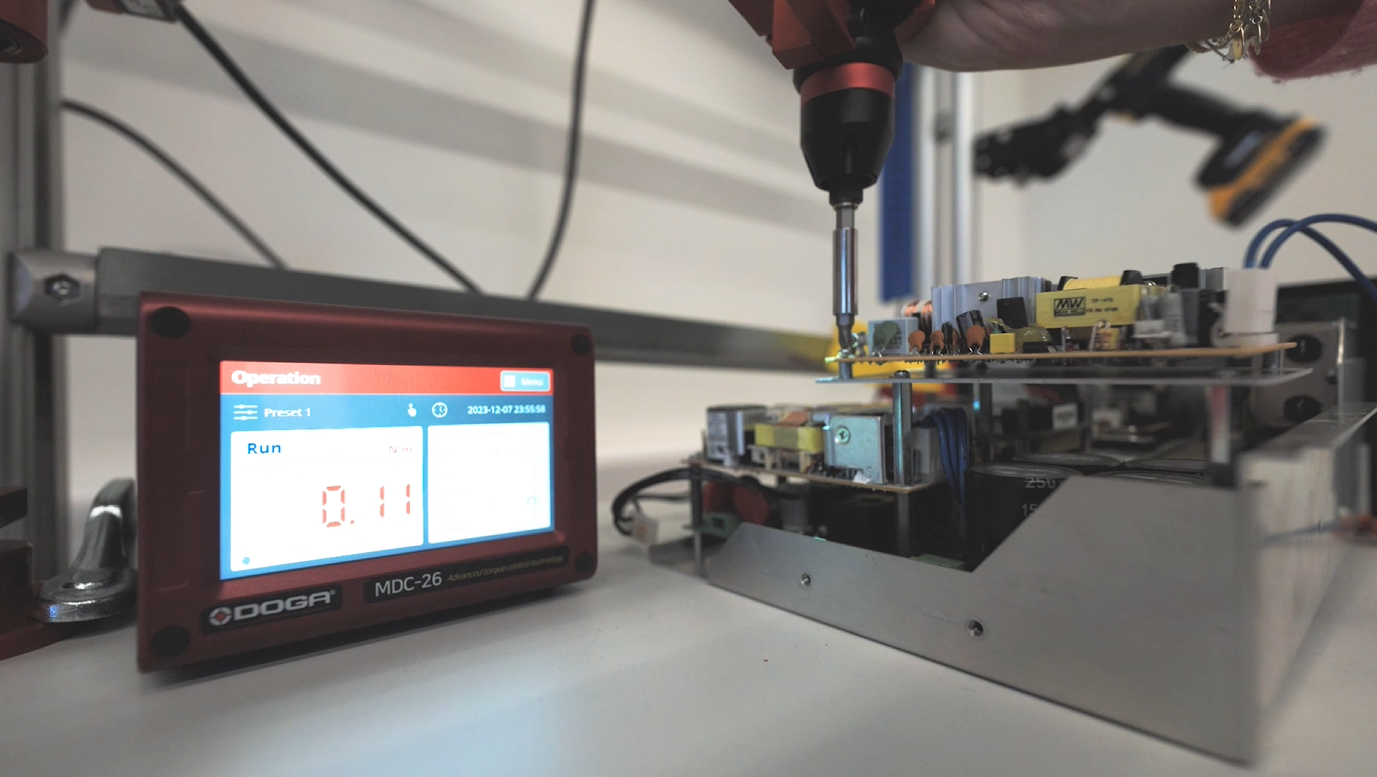

Electric screwdrivers are designed for precision fastening at smaller torque ranges, typically below 10–15 Nm. Brands like DOGA specialize in this segment, offering tools that prioritize accuracy, ergonomics, and control in light assembly operations.

Low-torque tools are available in both cabled (corded) and battery-powered versions: cabled tools offer continuous power and maximum consistency for fixed workstations, while battery tools provide greater mobility and flexibility but require charging and careful battery management to maintain uptime.

These tools are commonly used for critical applications and industries such as electronics, medical devices, small appliances, and automotive interior assembly, where delicate fasteners and components require consistent but gentle torque.

| Smart Cabled Screwdrivers | Smart Battery Screwdrivers | ||||||

| DOGA | DOGA | DOGA | ESTIC | MAKITA | STANLEY | ESTIC | |

| Brand |  |  |  |  |

|  |  |

| Model |  |  |  |  |  |  |  |

| Tool Name | GX/GY series | MDC series | MDT series | Micro Tools | MTC series | QBE series | EHC series |

| Covering Range | 0,09…10Nm | 0,01…49Nm | 0,01…49Nm | 0,1…5Nm | 0,5…40Nm | 1…90Nm | 1…100Nm |

| Versions | Pistol, Straight | Pistol, Straight, Angle | Pistol, Straight, Angle | Straight | Pistol, Angle | Pistol, Straight, Angle | Pistol, Angle |

| Number of presets | 1 | 16 | 16 | 99 | 1 | 256 | 99 |

| Drive | Clutch | Current Control Direct Drive | Transducerized Direct Drive | Transducerized Direct Drive | Clutch | Transducerized Direct Drive | Transducerized Pulse |

| Monitoring | OK/NOK | Torque & Angle data | Torque & Angle data | Torque & Angle data | OK/NOK | Torque & Angle data | Torque & Angle data |

| Communication | I/O | Open Protocol | Open Protocol | Open Protocol | WiFi | Open Protocol | Open Protocol |

| Controller | XT/XT series | MDC26/32 | MDT26/32 | Handy 2000 micro | MTC | QB/SC series

| EHC2-MIFseries |

| Tool Brand Name | GX/GY series | MDC series | MDT series | Micro Tools | MTC series | QBE series | EHC series |

|  |  |  |  |  |  | |

| Controller capacity | 1 screwdriver per controller | 1 screwdriver per controller | 1 screwdriver per controller | 1 screwdriver per controller | N/A | up to 6 wireless screwdrivers/controller | up to 10 wireless screwdrivers/controller |

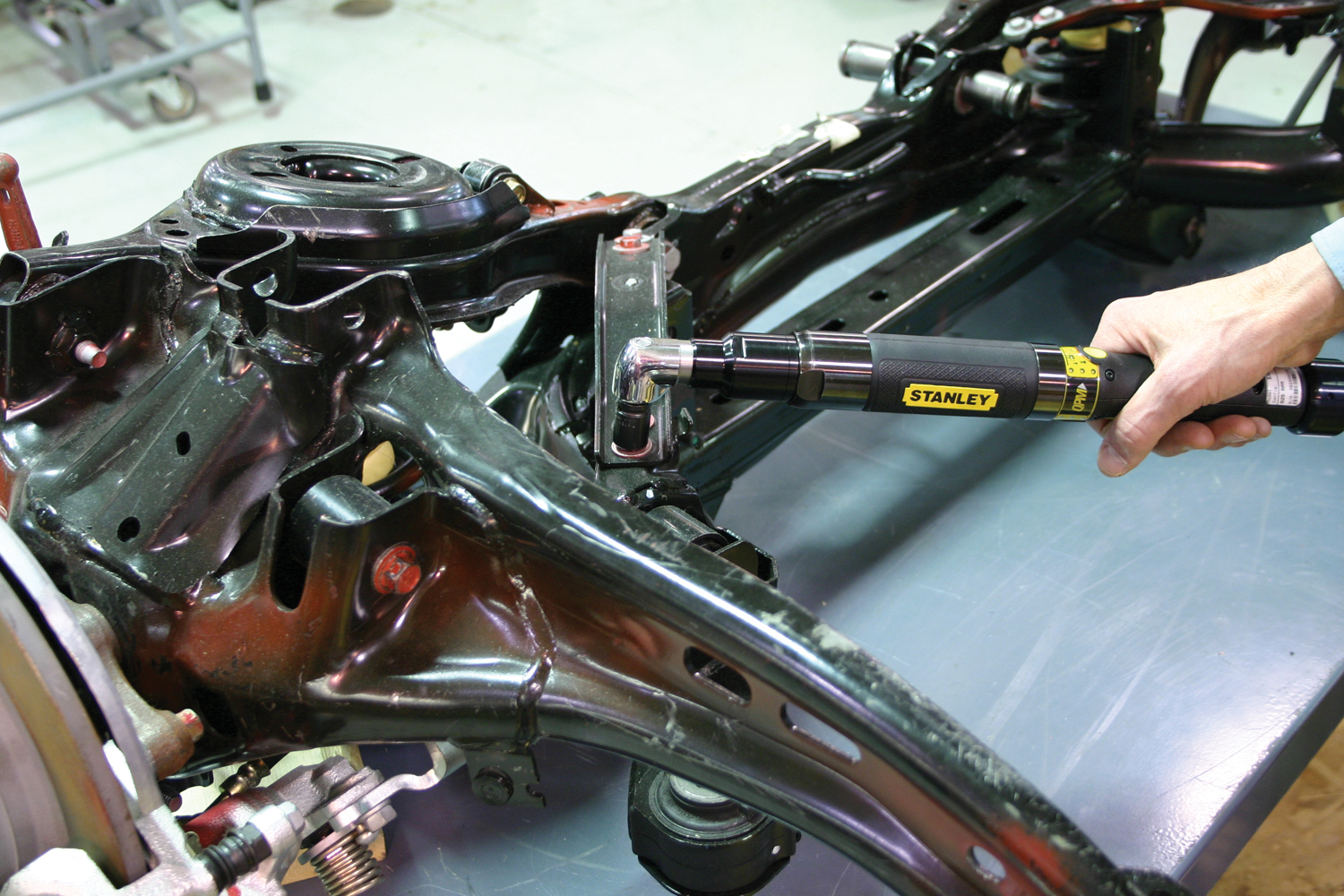

Electric nutrunners are industrial tightening systems built for medium- to high-torque, safety-critical joints. They are typically DC tools connected to a controller that provides advanced measurement, monitoring, and error-proofing.

These tools are designed for structural applications requiring higher tightening forces, generally starting at 15 Nm and extending to several hundred newton-meters. Manufacturers such as Stanley offer solutions for automotive chassis, powertrain, aerospace, and heavy machinery environments, where joint quality is non-negotiable.

Electric nutrunners guarantee process reliability, traceability, and joint safety, making them indispensable in demanding industrial assembly applications where failure is not an option.

| Electric Hand-held Nutrunners | Electric Spindles | |||||

| STANLEY | ESTIC | YOKOTA | NORBAR | STANLEY | ESTIC | |

| Brand |  |

|  |  |

|  |

| Model |  |  |  |  |  |  |

| Tool Name | QB series | EH2 series | E-wrench | EvoTorque | QB series | EH2 series |

| Covering Range | 0,5…400Nm | 1…180Nm | 3…90Nm | 100..7000Nm | 1…2200Nm | 1…600Nm |

| Versions | Pistol, Straight, Angle | Pistol, Angle | Pistol | Pistol | Straight | Straight, Angle |

| Number of presets | 256 | 99 | 16 | 1 | 256 | 99 |

| Drive | Transducerized Direct Drive | Transducerized Pulsing | Transducerized Pulsing | Transducerized Direct Drive | Transducerized Direct Drive | Transducerized Direct Drive |

| Reaction device needed? | yes | no | no | yes | yes | yes |

| Monitoring | Torque & Angle data | Torque & Angle data | Torque & Angle data | Torque & Angle data | Torque & Angle data | Torque & Angle data |

| Communication | Open Protocol | Open Protocol | Open Protocol | none | Open Protocol | Open Protocol |

| Controller Brand Name | SC Series | HT45/50 series | YETC series | direct 220VAC | SC Series | HT45/50 |

| Controller Model |  |  |  | N/A |  |  |

| Controller capacity | 1 tool/controller | 1 tool/controller | 1 tool/controller | N/A | 1 tool/controller | 1 tool/controller |