In manufacturing, assembly combines individual parts into a finished product, while a subassembly is a smaller unit made from multiple parts that feeds into the final build.

Automation levels depend on volume and standardization: high-volume, repetitive work is often automated, while the rise of small-batch and customized products keeps many assembly tasks manual. In these less-automated settings, clear operator guidance is essential to maintain quality, reduce errors, and support frequent product changes.

Research indicates that nearly 70% of shop floor activities are still performed manually, making production processes vulnerable to errors, inefficiencies, and inconsistencies. This is especially true in high-mix, low-volume (HMLV) assembly environments, where flexibility and customization are essential but come with significant operational challenges.

To overcome these challenges and ensure accuracy, efficiency, and traceability, manufacturers are turning to modern technologies such as digital work instructions, pick-to-light and put-to-light systems, machine vision inspection, and more. These solutions help standardize processes, minimize errors, and enhance overall productivity, building a more flexible, connected, and resilient manufacturing environment.

Digital solutions driving precision and productivity in modern assembly.

Convert paper-based manuals into digital instructions

Projected visual cues onto the work area

Validate correctness of worker handlings

Fasten bolts in right sequence at right torque

Locate and confirm events in 3D space

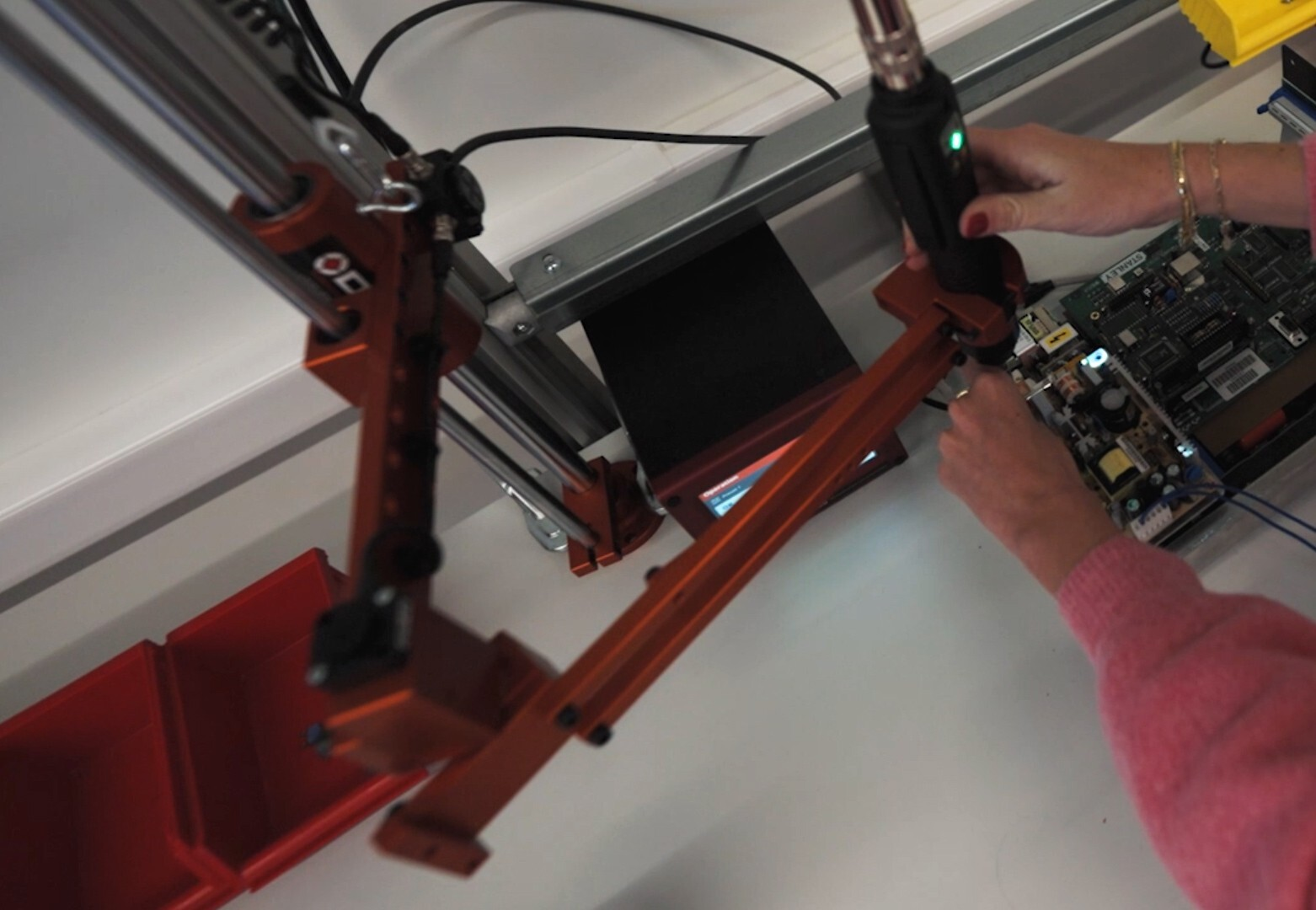

Digital work instructions (DWIs) are electronic versions of traditional paper-based manuals that guide operators step-by-step through assembly or operational tasks using digital devices such as PCs, tablets, or smartphones.

Advantages

Considerations

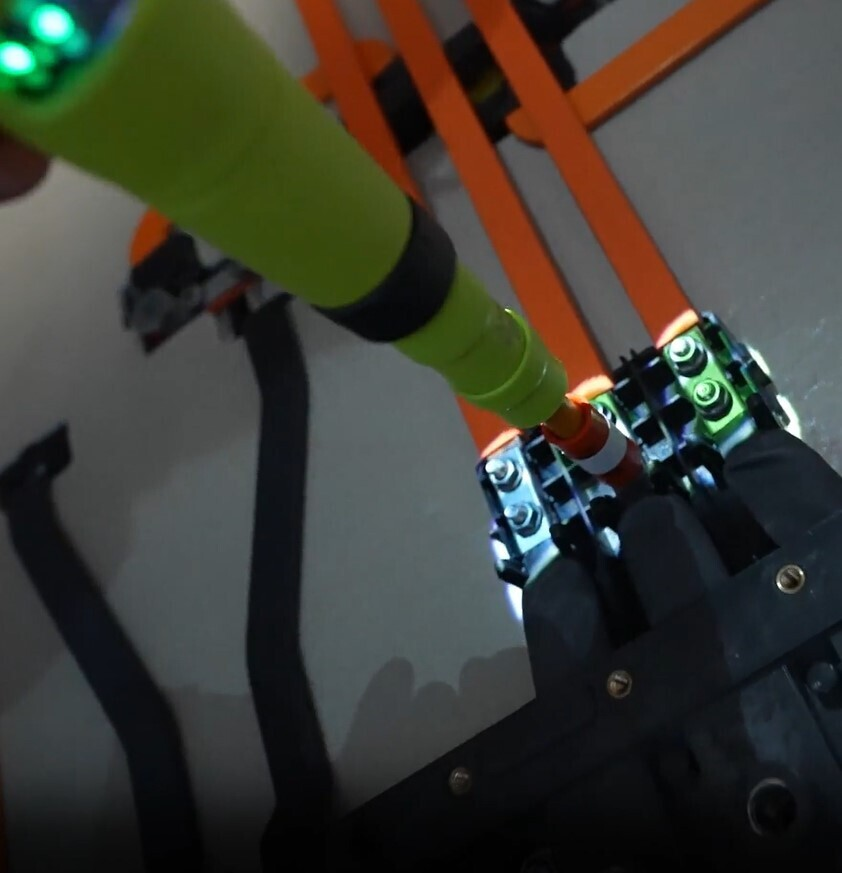

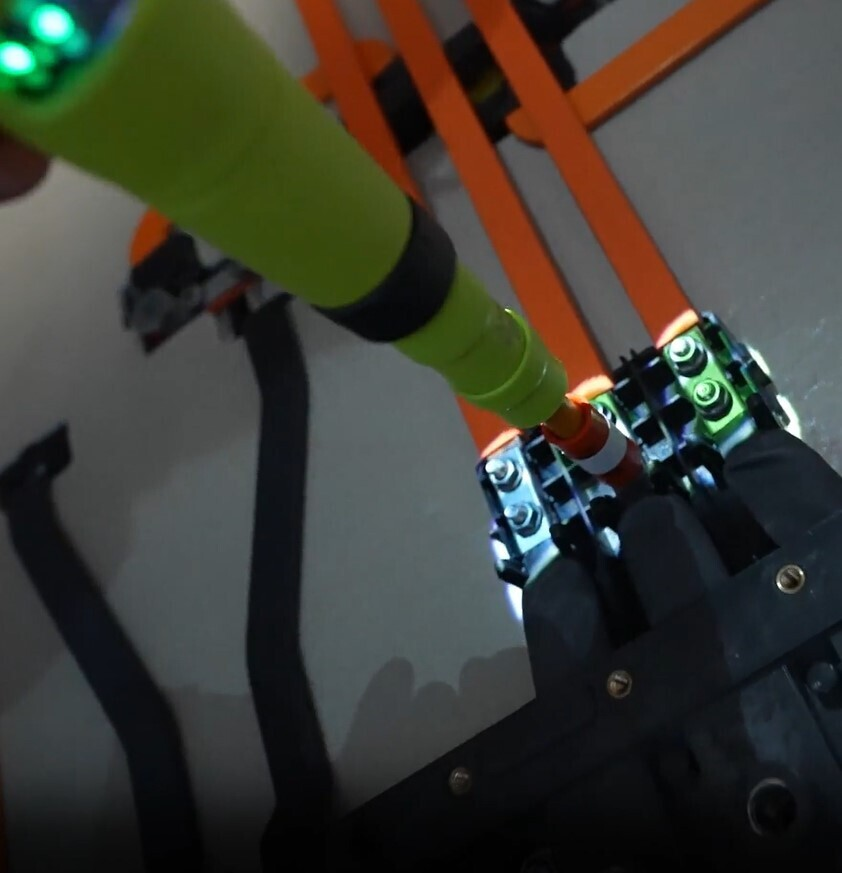

Projection-based augmented reality (AR) is a technology that projects digital information, such as text, images, or visual cues, directly onto a physical surface or workspace, instead of displaying it through a screen.

Advantages

Considerations

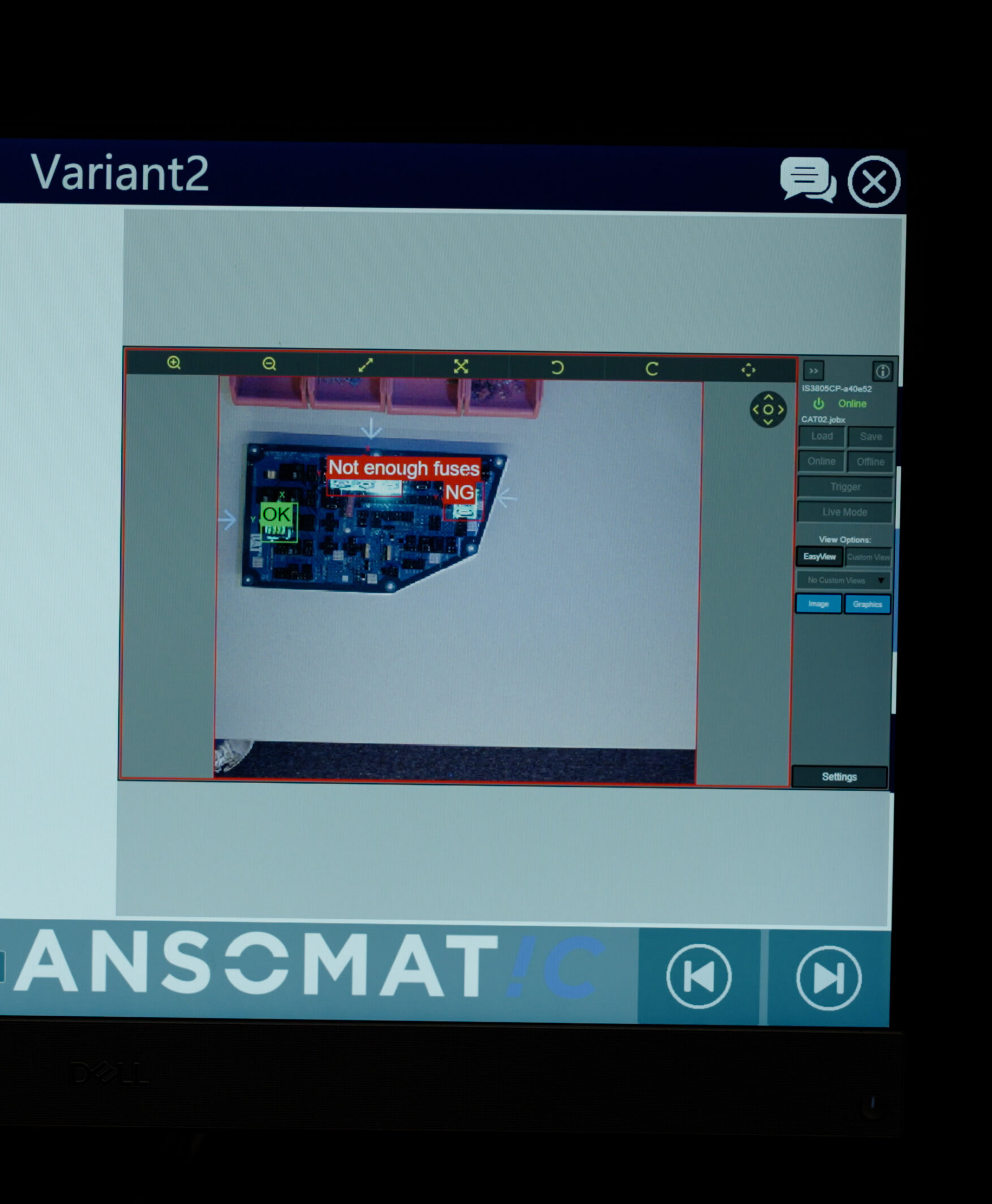

Machine vision is a technology that uses cameras and image-processing software to automatically monitor, analyze, and verify visual aspects of production or assembly tasks. In operator guidance, machine vision acts as an intelligent assistant - observing the work being performed and providing real-time feedback to ensure each step is executed correctly.

Advantages

Error prevention: instantly detects incorrect parts, missing components, or wrong assembly sequences before they cause rework.

Considerations

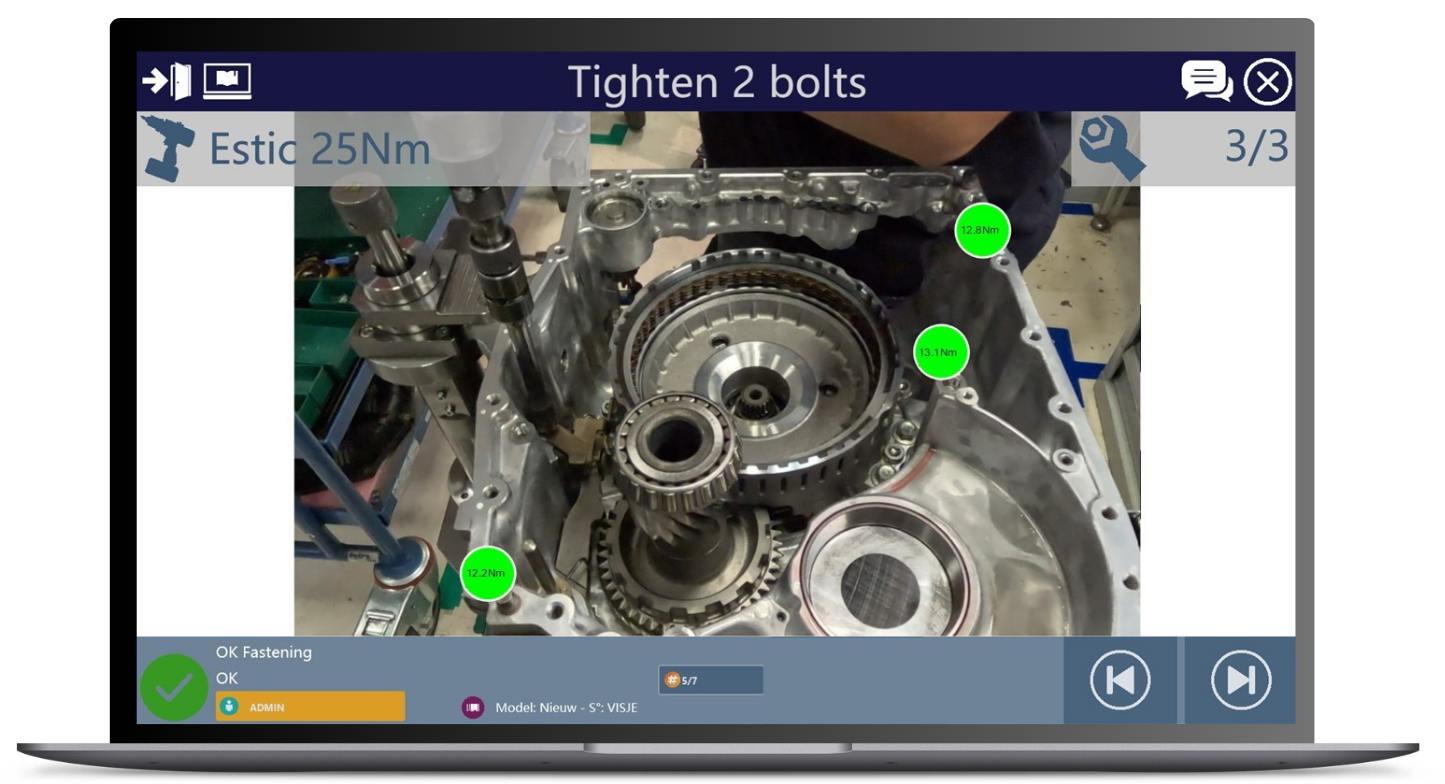

A tightening tool is used to fasten bolts, screws, or nuts to a specific torque or angle, ensuring joints are secure and consistent. In manual or semi-automated operations, these tools rely heavily on operator guidance, clear instructions help to maintain quality and prevent assembly errors by following proper sequences.

Advantages

Considerations

Real-Time Location Systems (RTLS) are technologies that track and monitor the precise location of assets, tools, materials, and even people within a production or assembly environment. By continuously capturing and transmitting location data, RTLS provides real-time visibility of all activities on the shop floor.

Advantages

Considerations

| Technology | Advantages (Pros) | Considerations (Cons) | Best Use / Ideal Application |

| Digital Work Instructions | • Clear, visual, and interactive guidance reduces interpretation errors. • Always up-to-date with version control and approval workflows. • Improves productivity and traceability • Supports standardization and continuous improvement. | • Needs user training and familiarity with digital tools. • Dependence on digital devices (PC, tablet). | Best for manual or semi-automated assembly where standardized, guided workflows and traceability are essential. |

| Projection-Based Augmented Reality (AR) | • Hands-free operation allows full focus on the task. • Visual “follow-the-light” guidance minimizes errors. • Accelerates operator training • Quick and cost-effective setup using standard projectors. | • Requires content creation. • Best suited for fixed workstations. | Ideal for visual assembly guidance and training environments where operators benefit from projected cues directly on the work surface. |

| Machine Vision | • Detects incorrect parts or assembly errors instantly. • Enables real-time feedback and automated process flow. • Provides visual traceability • Give reason code for potential mistakes | • Requires precise lighting and camera setup. • Environmental factors can affect detection accuracy. | Best for quality-critical processes and error-proofing steps where visual verification and traceability are key. |

| Fastening (Smart Torque Tools) | • Ensures correct torque/angle for each fastener. • Prevents under- or over-tightening. • Records torque data and operator IDs for traceability. | • Higher investment for electronic tools. • Ergonomic considerations for operator comfort. | Best for mechanical assemblies requiring precision fastening and process verification (e.g., automotive, aerospace, machinery). |

| Real-Time Location System (RTLS) | • Hyper-accurate (up to 1.5 mm) position tracking. • Prevents errors by verifying correct part/tool usage. • Scalable factory-wide coverage. • Tracks in 3D, beyond vision’s 2D limits. • Useful for asset tracking, safety, and logistics. | • Requires infrastructure (anchors, sensors). • Needs line of sight to multiple anchors for accuracy. • Initial setup and calibration effort. | Best for large scale factory implementations in 3D space |