The electronics & high tech manufacturing market is experiencing rapid growth, driven by strong global demand for semiconductors and advanced electronic components. To stay competitive, manufacturers are moving toward modular, reconfigurable production lines that enable faster product changeovers, support multi-SKU builds, and adapt easily to increasing product customization.

As the High Tech & Electronics industry continues to advance, manufacturers face a new set of challenges that come with increased complexity and precision requirements:

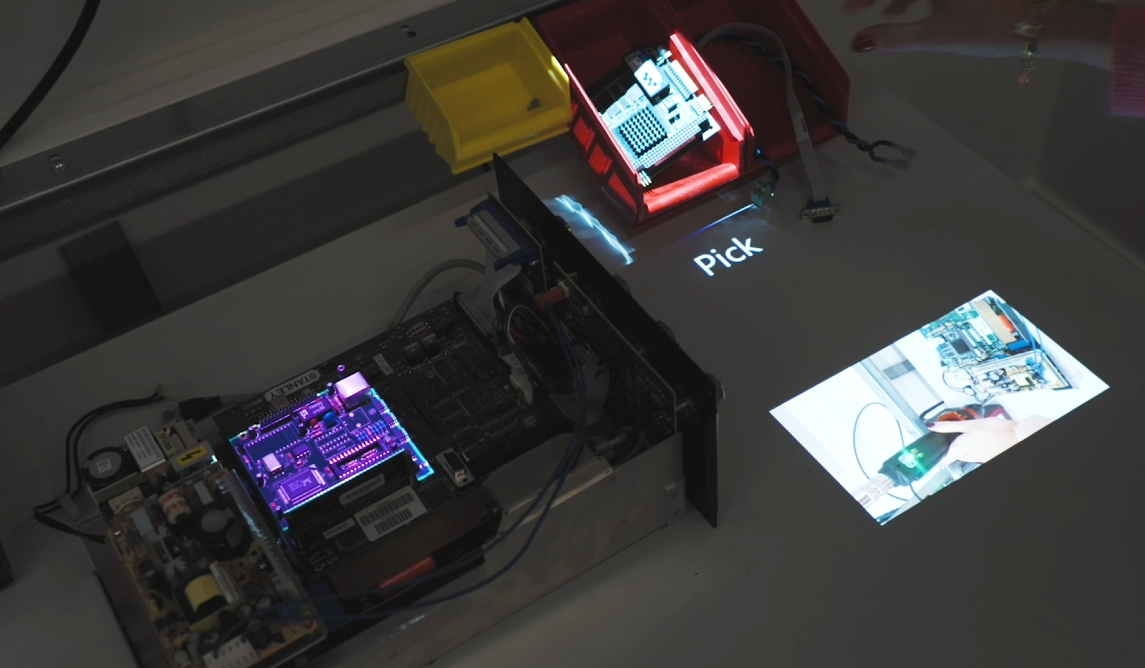

Operator guidance is increasingly used in high-tech and electronics assembly environments. These processes often involve multiple connectors, plugs, and fine-pitch components, characterized by high variation and delicate, precision-based work. Even a small mistake can have severe consequences, such as product failure or costly rework.

Electronics assembly requires low-torque, precision fastening tools equipped with positioning arms to ensure accuracy, repeatability, and operator comfort when working with delicate components and fine threads.