As manufacturing operations grow more advanced and dynamic, the demand for clear, reliable, and real-time instructions continues to rise. Traditional paper manuals, static PDFs, and outdated files can no longer keep pace with modern production needs. Digital work instructions bring a new level of precision and flexibility to the shop floor, helping operators perform complex tasks with confidence, consistency, and accuracy.

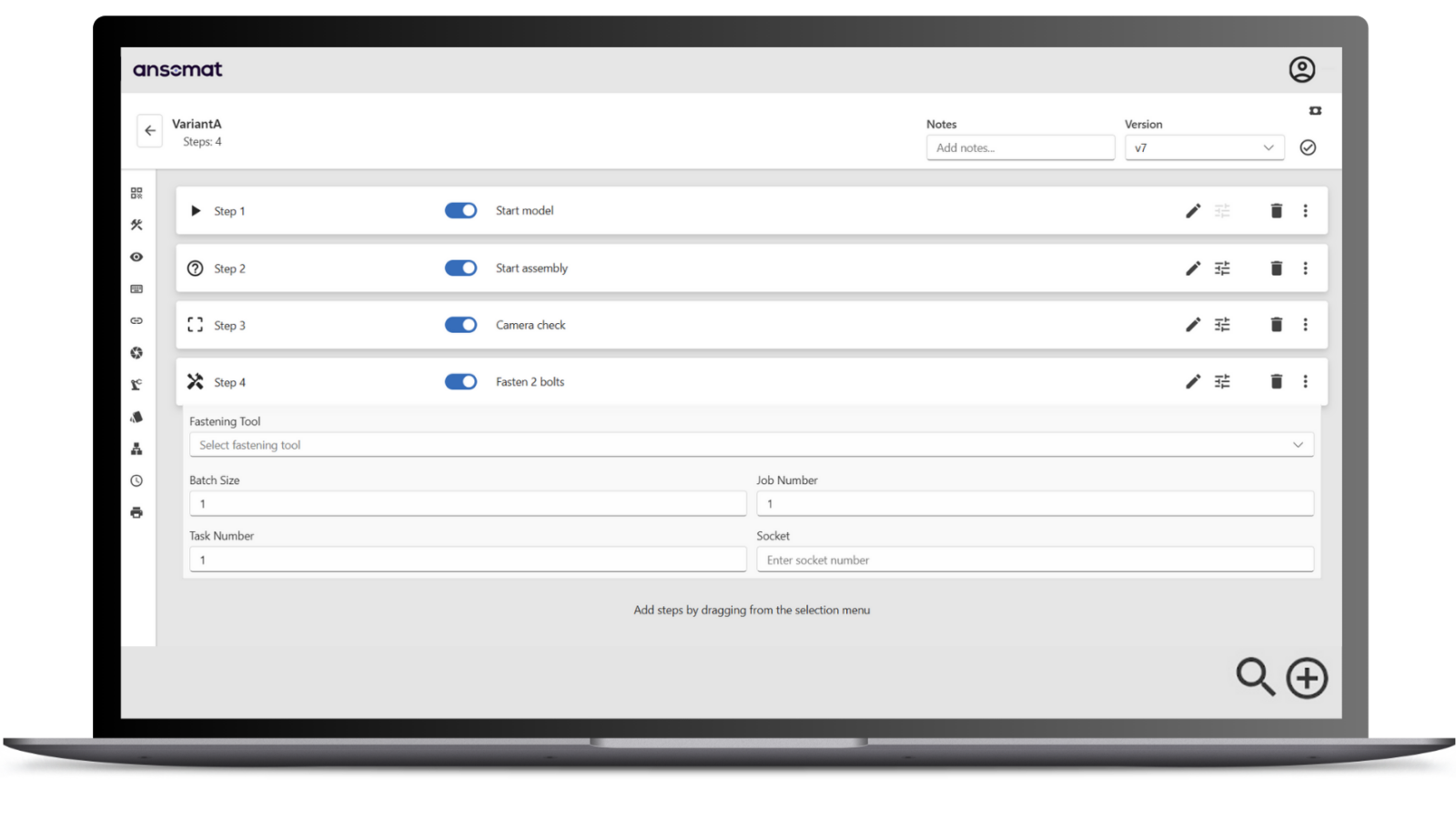

Whether your goal is to support high-mix, low-volume assembly, accelerate operator onboarding, or reduce process variation, digital work instructions provide a connected, scalable solution that drives your digital transformation forward.

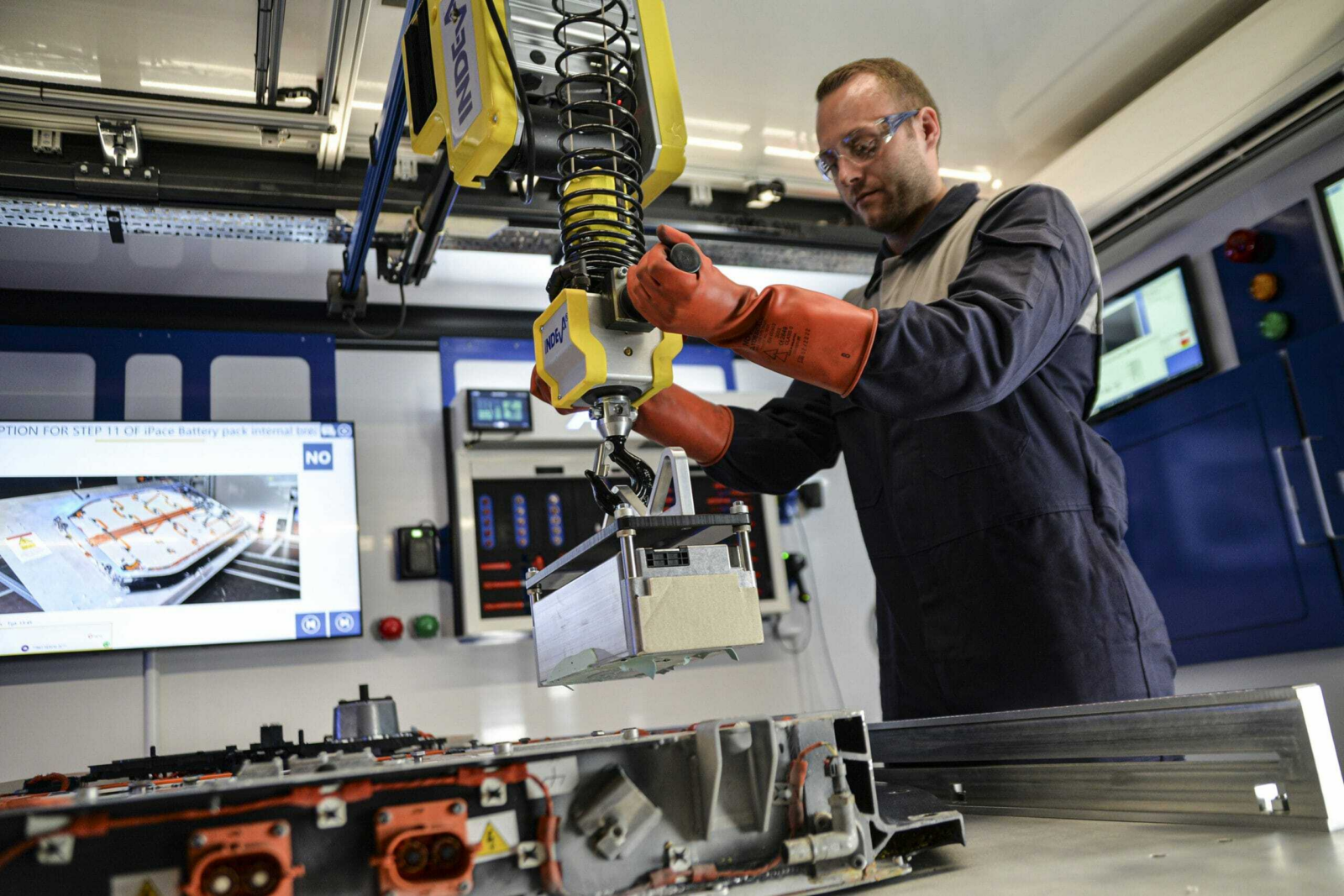

Digital work instruction solutions are interactive, often visual, step-by-step instructions delivered through digital devices such as tablets, pc-screens, or augmented reality systems. They break down complex tasks into manageable steps, providing visual cues, guidance, and checks that make it easier for operators to complete their work correctly and efficiently.

By moving away from printed manuals and outdated files, manufacturers ensure that operators always follow the latest version of the process, increasing standardization and reducing human error.

If any of these conditions apply to your shop floor, transitioning to digital work instructions can significantly improve performance and reduce risk.

NEW

Remotely, efficiently and at scale