In today’s fast-changing manufacturing landscape, human–machine integration is key to efficiency and competitiveness. Since full automation remains challenging, many manufacturers adopt semi-automated assembly, combining human flexibility with machine precision. Supporting operators with smart technologies builds the foundation for scalable, resilient, and high-performing production.

Human–Machine Interaction (HMI) in modern manufacturing defines how operators and digital systems collaborate to execute production tasks efficiently, safely, and consistently. In today’s connected factories, machines, tools, and devices continuously share data that informs and guides the operator’s next actions. Each workstation often depends on multiple inputs, confirming correct parameters, capturing measurements, and validating process steps. All of which must be clearly communicated to the user.

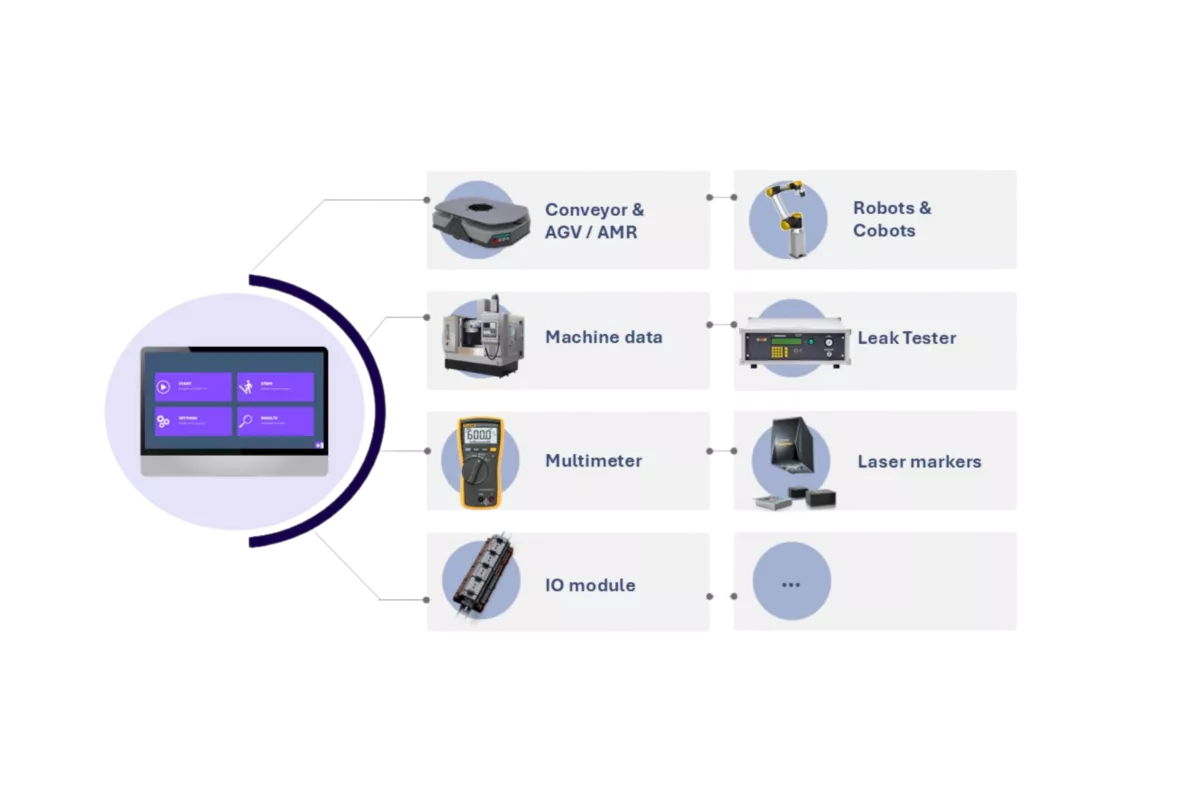

A holistic operator guidance system plays a key role in this environment. Rather than functioning as a standalone station, it integrates seamlessly with the entire shop floor, connecting diverse tools and devices through standardized interfaces. This connectivity ensures information flows smoothly across processes, reducing custom programming and maintaining flexibility throughout the production lifecycle.

It is essential that an operator guidance system can seamlessly connect with the tools and equipment on the shop floor. Such a system should not function as an isolated station but rather as an integrated part of the broader production environment, this is a critical consideration.

Typically, HMIs are programmed by PLC engineers and are highly customized, which makes them difficult to maintain and adapt, especially when managing a wide range of product variants.

With our operator guidance system, any type of shop floor device can be connected through a standardized interface. This approach significantly reduces the need for custom programming and ensures flexibility throughout the entire process lifecycle.

Lightweight and efficient data exchange

In connected manufacturing, MQTT (Message Queuing Telemetry Transport) enables fast, reliable communication between machines, sensors, and operator guidance systems. Its lightweight design transmits only essential data, reducing network load and latency for real-time responsiveness across the shop floor.

Seamless Integration and Scalability

With its open-standard architecture, MQTT easily integrates new machines, robots, and tools without complex reprogramming. This flexibility allows manufacturers to scale or modify production lines quickly, ensuring smooth data flow for Industry 4.0 environments.