Considering a study of Kearny , Humans perform nearly 3 out of 4 tasks on the factory floor. However their performance is almost invisible for factory analytics.

Improving data visibility on human tasks will empower manufacturers to find improvement opportunities beyond machines.

Industry 4.0 has largely focused on automation and machine data, often overlooking the human element, yet people remain the greatest source of value in manufacturing because they can think, adapt, and innovate, unlike machines. However, human variability introduces challenges such as fatigue, distraction, or absence, which can lead to errors, defects, or even production recalls.

Key Challenges:

Complete process traceability

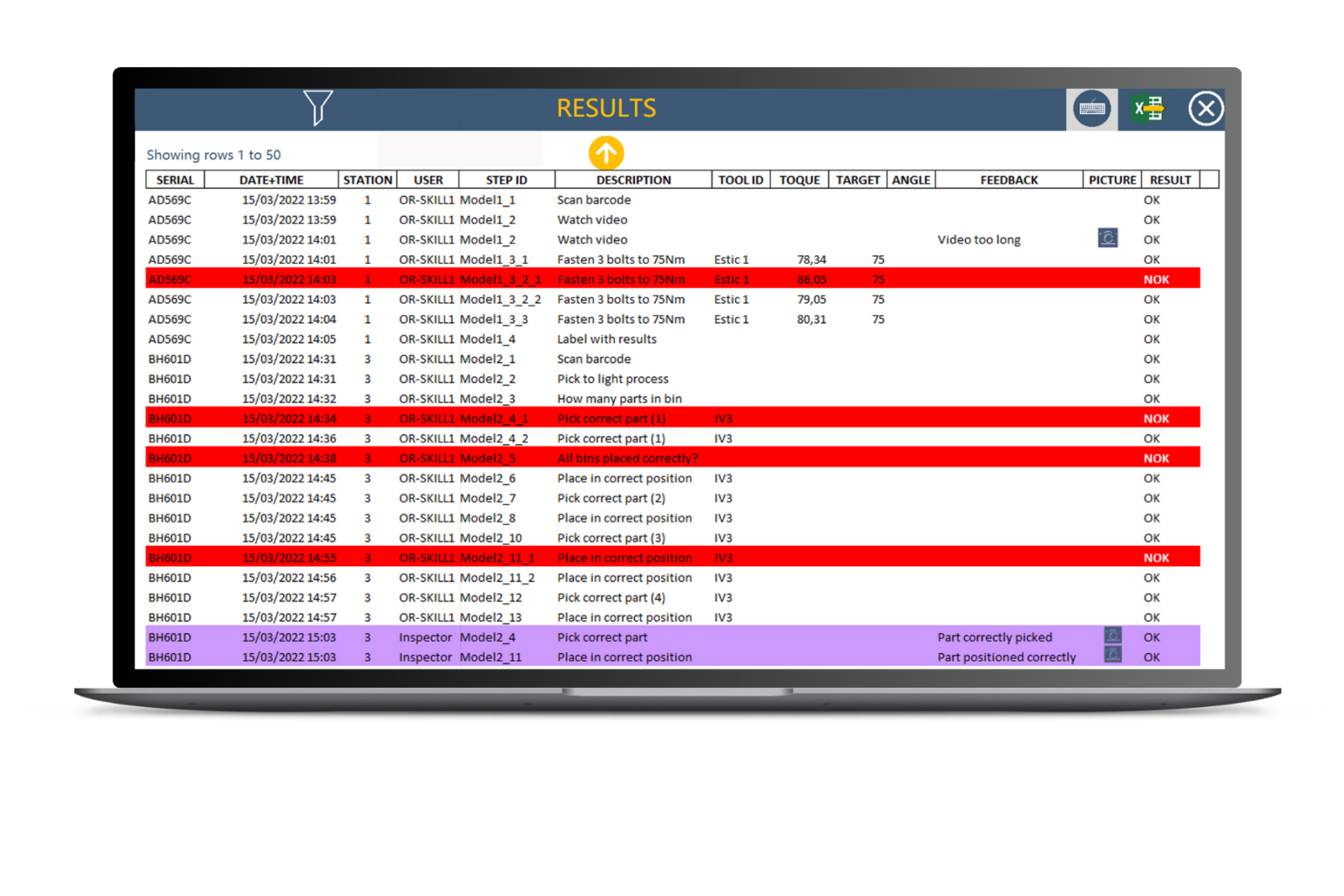

With an operator guidance solution, every step of the production process is automatically recorded. Key identifiers such as user ID, tool ID, station ID, and step ID are captured, along with detailed results like OK/NOK status, measured values, operator feedback, and photos. This ensures full visibility of what was done, when, and by whom, creating a solid foundation for traceability and accountability.

Structured data collection

All process information is stored in a central, organized data structure, making it easy to access and analyze historical records. By consolidating both human and machine data, manufacturers gain a complete picture of operations, connecting product quality, process performance, and operator activity in one unified system.

Each assembled product automatically receives its own digital birth certificate - a comprehensive record of all process data, operators involved, tools used, and test results. This guarantees end-to-end traceability from assembly to shipment, ensuring compliance, simplifying audits, and providing a reliable quality history for every unit produced.