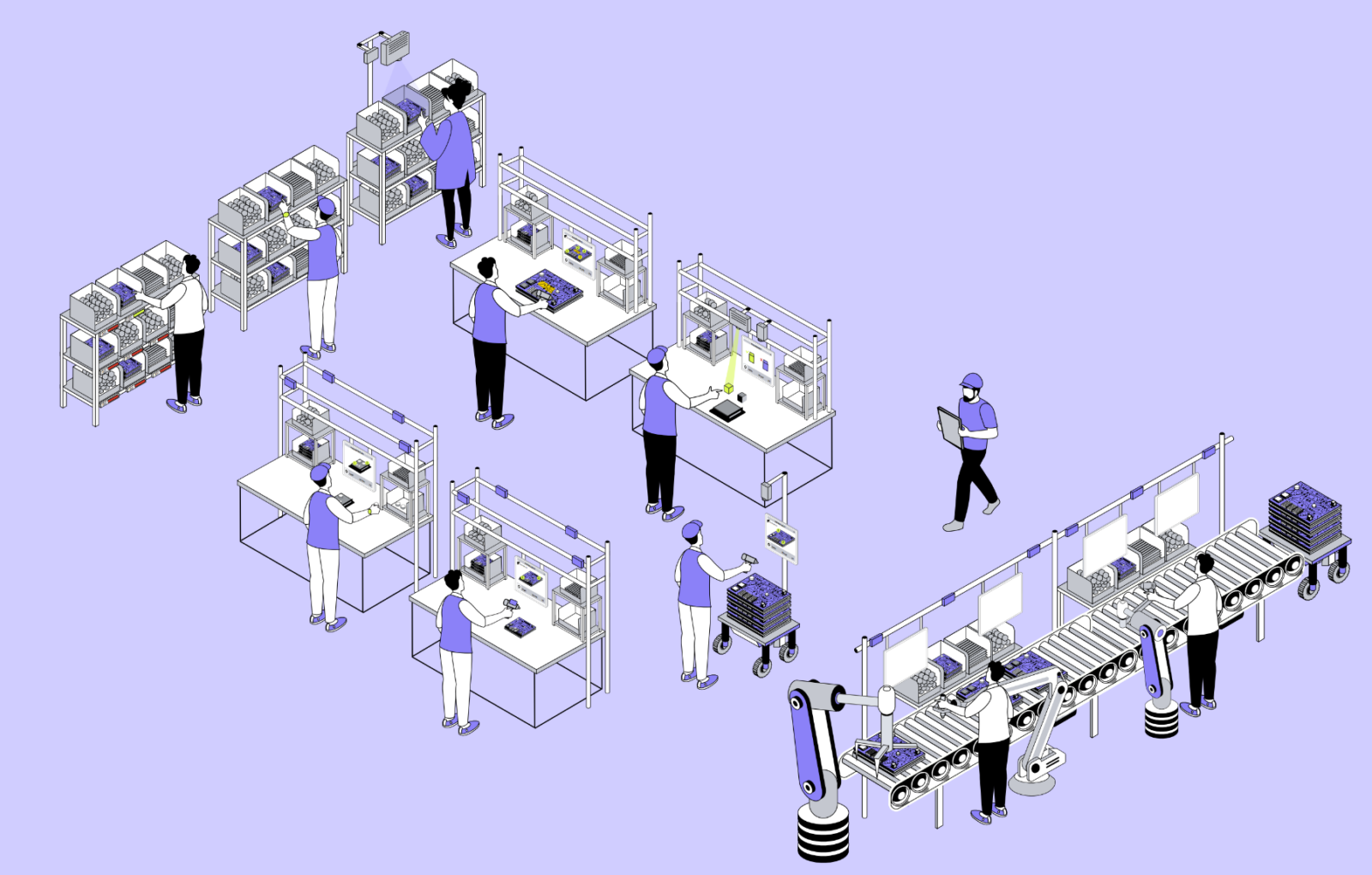

Our award-winning operator guidance system enhances the quality, consistency, and traceability of all manual operations on the shop floor. From digital work instructions and AR-projected work instructions to smart tools & device integrations with machine vision, sensors, RFID, RTLS, and other tech, it enables fully connected, error-proof production.

An operator guidance system leads operators step by step through each task, workflow, or assembly process. It replaces paper-based instructions with interactive digital work instructions, shown on screens or projected directly onto the work area using augmented reality (AR). In addition, the system integrates error-prevention and quality-assurance tools to verify every process step. All actions are automatically logged and tracked, ensuring full traceability, process transparency, and compliance across the shop floor.

The Ansomat operator guidance platform is applied across multiple shop floor processes, enabling seamless interaction between operators, machines, tools, robots, and production systems. It ensures that every task is executed correctly, in the right sequence, and with complete digital traceability, supporting higher quality, lower error rates, and continuous process improvement.

As production processes grow more complex, particularly with the shift toward high-mix, low-volume manufacturing, it becomes increasingly difficult for shop floor workers to stay up to date with every requirement. Our operator guidance system removes the need to memorize instructions by delivering them in an immersive, intuitive format, allowing anyone to perform tasks with confidence.

Learn faster, onboard quicker and train more efficiently. Training takes place directly on the shop floor, enabling workers to develop skills in real working conditions without disrupting production or relying on specialists. Even less experienced employees can handle more advanced tasks, a major advantage in times when skilled labor is in short supply.

Nothing impacts budgets faster than rework or product recalls. Our operator guidance system has proven to reduce error rates to nearly zero.

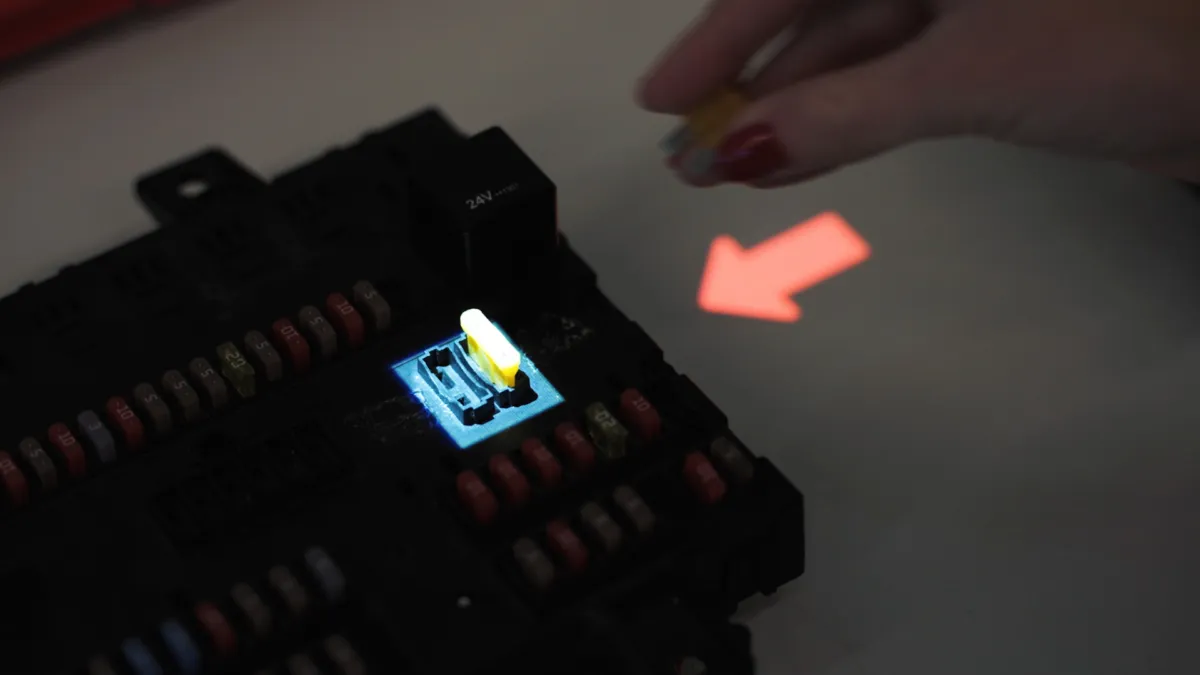

Each process step can be validated through external devices, shifting critical decisions from the operator to objective system verification, a concept known as “no-fault-forward” production. This approach prevents errors at the source rather than correcting them later down the line.

When a fully automated line isn’t cost-effective, investing in operator-centric semi-automation provides the perfect balance between efficiency, flexibility, and quality.

Introducing digital work instructions is often perceived as time-consuming for the engineering team or offering limited value. Our operator guidance platform makes it fast and intuitive to configure and connect devices across all stations. With only half a day of training, teams are ready to start, accelerating adoption and delivering value from day one.

No programming expertise is required. We believe everyone should be empowered to create and maintain their own work instructions.

Operator guidance reduces shop floor errors by breaking complex processes into clear, step-by-step instructions that guide operators through each task in the correct sequence. The level of detail can be adapted to the operator’s skill and experience, providing more guidance for new employees and streamlined instructions for experienced workers.

Unlike traditional paper-based work instructions, which are difficult to search, rarely consulted, visually unclear, and impossible to control, operator guidance delivers digital and AR-based instructions directly at the workstation. Each process step can be monitored and validated using connected tools and devices, ensuring it is completed correctly before moving forward. This structured, controlled approach prevents errors at the source and supports zero-defect production.

Digital work instructions provide operators with digital versions of traditional instructions, such as text, images, or videos, displayed on a screen or workstation. While they improve accessibility compared to paper-based instructions, they remain passive and rely on operators to correctly interpret and execute each step.

Operator guidance, by contrast, is a broader and more comprehensive approach. It goes beyond displaying digital or AR-based instructions by actively guiding, controlling, validating, and verifying each process step through connected tools, devices, and production systems. The primary focus is on error prevention and zero-defect manufacturing, ensuring that mistakes are detected and prevented before they occur.

In short, digital work instructions explain what to do, while operator guidance ensures the task is performed correctly, consistently, and with full traceability.

Absolutely. Operator guidance system not limited to large enterprises. Our customers range from companies with as few as 20 employees to organizations with 1,000+ employees.

It’s a common myth that you need to be a large organization to benefit from connected work instruction platform. In fact, smaller companies often gain value even faster. Instead of investing in heavy, rigid automation systems, they can start with digital work instructions alone- gaining structure, consistency, and traceability while retaining the flexibility needed to adapt to frequent changes.

Digital work instructions scale with your business. You can begin with simple, operator-guided instructions and later add tools such as projectors, smart tools, or other connected devices as your needs evolve. This modular approach allows you to grow step by step, without overengineering from day one.

In short, digital work instructions offer a practical, flexible starting point for small companies—and a foundation that grows alongside them.