Supporting precision work on long aerospace structures

The Challenge

Producing large aerospace components introduces significant quality challenges.

- Uncertainty around correct hole placement

- Difficult and costly quality control on long parts

- Paper-based instructions with no real-time validation

- No traceability of operator performance during critical assembly steps

These issues made it harder to consistently ensure quality in the wing assembly process.

The Solution: Project LEAD

Spirit’s Project LEAD demonstrates how off-the-shelf technologies can be combined to create a next-generation digital assembly environment, powered by the Ansomat Operator Guidance System.

Ansomat provides digital work instructions and integrates:

- Smart tools and RFID-based tool registration

- Augmented reality work instructions

- Legacy tooling and utilities monitoring

- Full control of the method of manufacture

The LEAD Cell actively responds to operator actions, guiding each build step and capturing data throughout the process.

How It Works -the Ansomat turnkey enabler:

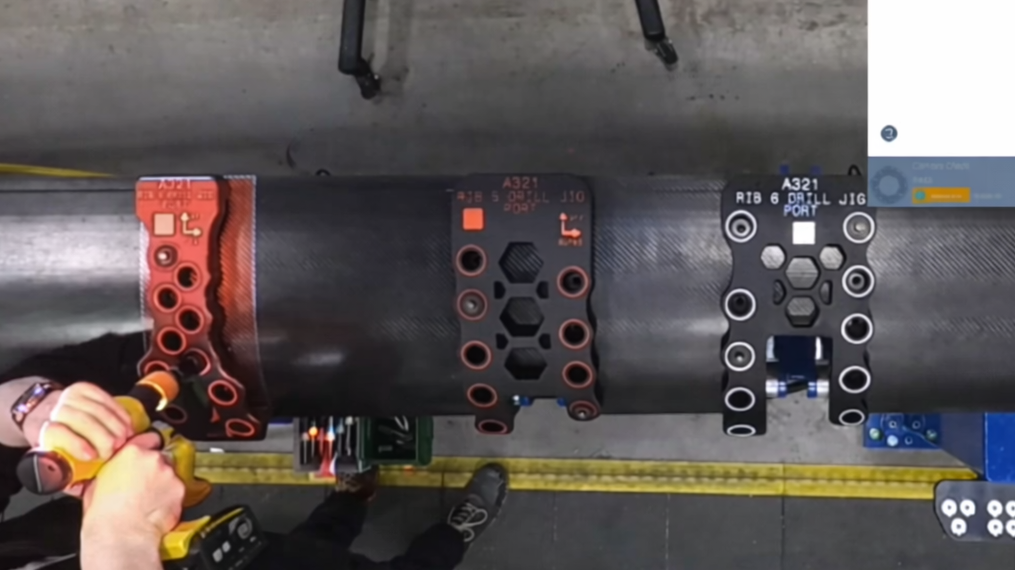

- Augmented Reality guidance highlights the correct drilling locations in real time

- A powered Gantry - A sliding vision system and projector supports accurate work across a 14-meter workspace. It enables repositioning of the camera and projector system

- Automated process tracking through vision: work instructions move forward as the operator has completed tasks correctly

- Instructional videos on pc screen preview upcoming tasks to reduce errors

- Tailored instructions: different levels of instructions and guidance can be set-up based on an individual experience.

- Document Library: Operators are able to access a document library which could contain instructions, standards and videos.

- RFID Tool Register: tools are registered via RFID tags

- Solenoid Control: air tools enablement is controlled via solenoids

- Tooling Pin Control: camera checks that the tooling pins have been removed from storage

- Lifting Solution: A lifting jib allows a single operator to manoeuvre and position the panel

- Tooling Recognition: camera confirms the individual tool ID via QR codes

- Tool integration: Various types of tools can be integrated with the Ansomat system in different ways based on their intelligence

- DC Tools: the tool catprues and transfers torque and angle data to the control system

- EDU Position Control: The EDU (Electronic Drilling Unit) can be enabled based on its position. Tools are disabled until on correct drilling location

- A digital twin validates quality by logging and verifying every operator action

Book a demo

The Results

- In-process validation replaces costly downstream inspections

- Improved process repeatability across large assemblies

- High-resolution manufacturing data captured automatically

- Full traceability of operator actions and tool usage

Project LEAD enables accurate hole drilling, reduces uncertainty, and ensures consistent quality in critical wing assembly operations.

Instructions can be configured in zero-code environment

Spirit Aerospace

Process Lead

Book a 30 Days Free Trial

Experience our solution yourself.