Hydraulic valve assembly is physically demanding and extremely sensitive to small errors.

Each build involved heavy components, large numbers of nuts and bolts, and a long sequence of manual operations, creating multiple opportunities for mistakes.

The most critical issue was missing O-rings, which led to internal leakage, costly rework, and field failures. At the same time, poor ergonomics increased operator fatigue, further raising the risk of quality escapes.

Error-Proof, Ergonomic, Fully Traceable Assembly

The assembly cell was redesigned to guide the operator, verify every critical step, and capture complete process data.

Improved ergonomics and lower defect rates.

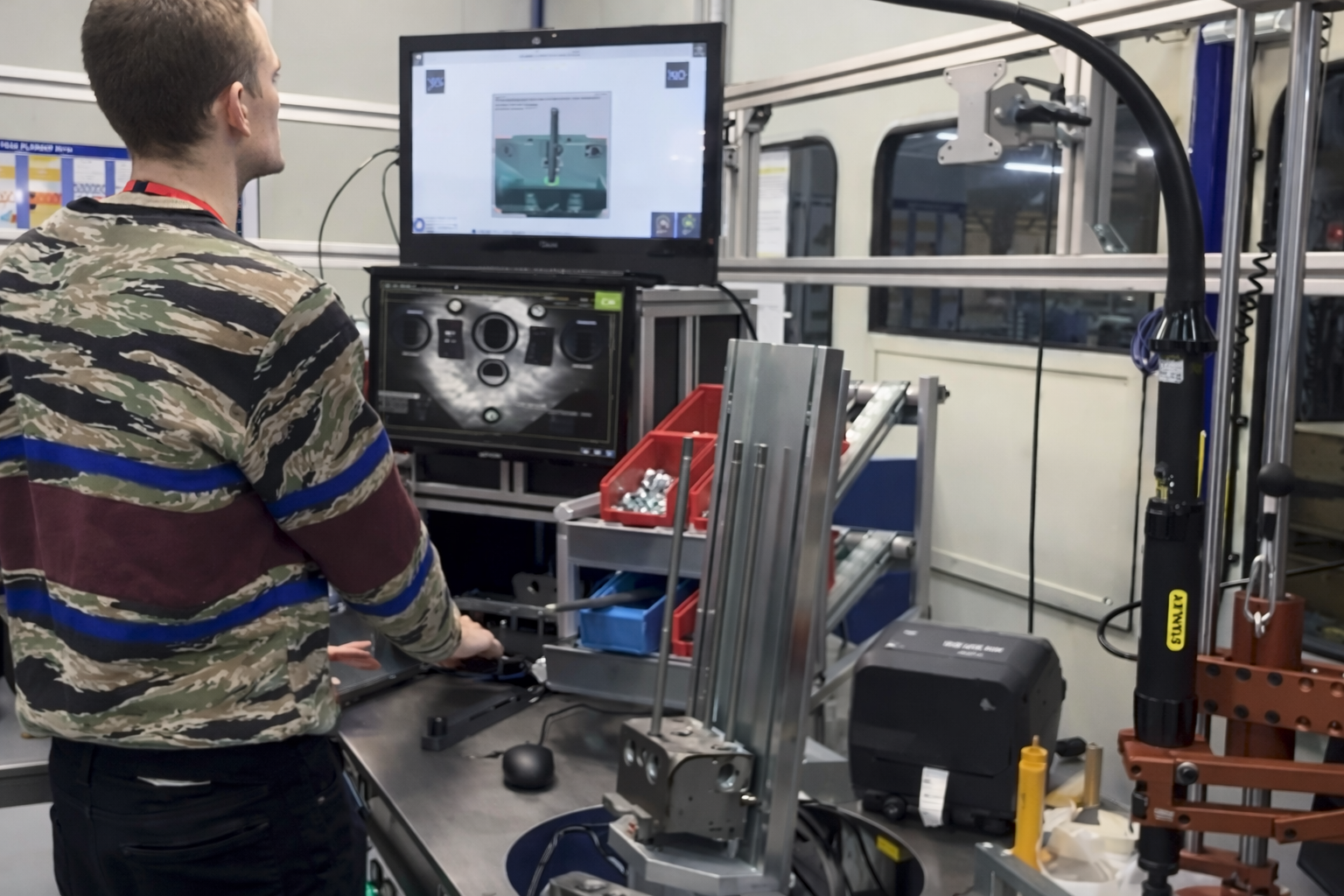

Machine Vision for O-Ring Verification

Automated vision confirms that every O-ring is present and correctly installed, eliminating the root cause of internal leakage.

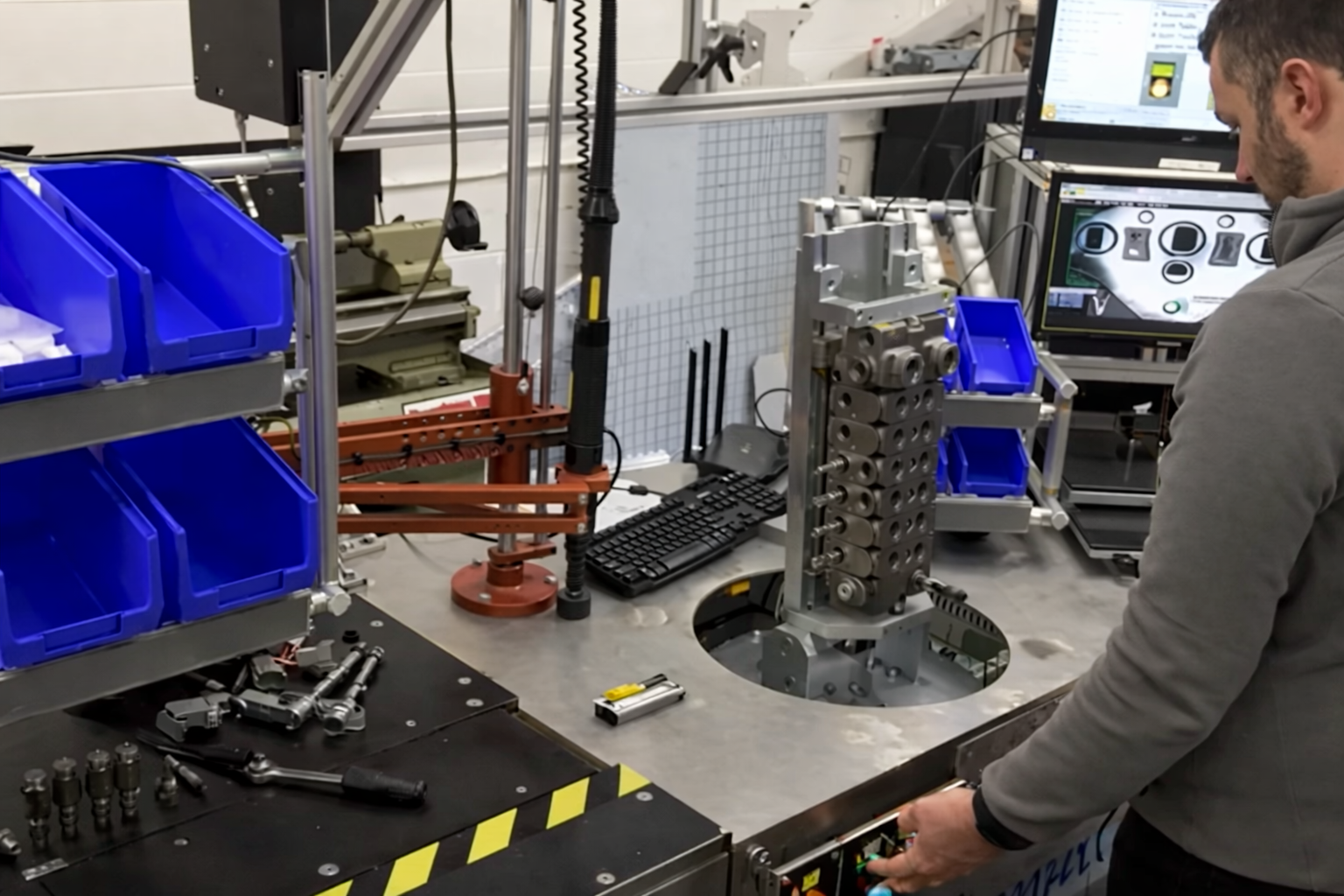

Height-Adjustable PLC-Controlled Fixture Positioning

Fixtures automatically move to the optimal working height, reducing strain and enabling consistent assembly posture for every operator.

Controlled Fastening Tools for Plug Installation

Torque and angle are continuously monitored through dc tools, with automatic feedback ensuring that every fastening operation meets specification.

Tool Position Control with Reaction Arm

Reaction arms ensure precise tool positioning, improving accuracy while removing physical load from the operator.

Automatic Socket & Program Selection

The correct socket and tightening program are loaded automatically, preventing configuration errors and speeding up the workflow.

With quality verification embedded directly into the process, defects are prevented rather than detected downstream.

For high-value hydraulic assemblies, a single missing seal can compromise the entire product. By combining ergonomic workstation design with machine vision, controlled fastening, and automated program selection, Parker now builds every valve with confidence, while capturing a complete digital record of how it was made.