As electric vehicles become more common, keeping their batteries healthy for as long as possible is crucial. Unlike traditional engines, EV batteries don’t yet have clear repair standards, making battery reliability a growing challenge.

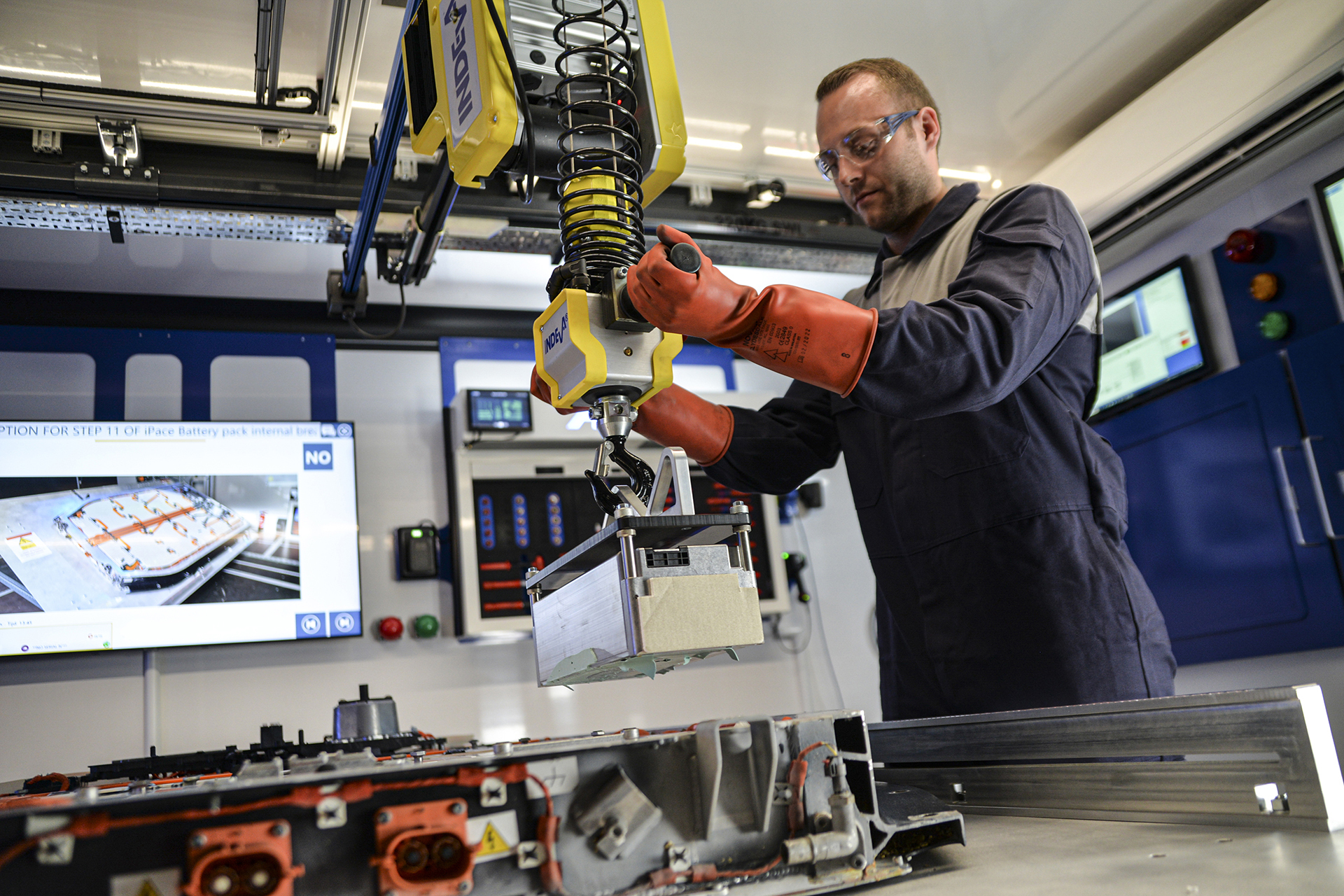

Remanufacturing restores used batteries to near-new condition by identifying and replacing faulty modules, rather than scrapping the whole pack. While batteries naturally degrade over time, many faults are caused by a small number of weak cells. Using advanced diagnostics, these faults can be detected early and repaired through processes such as Autocraft’s REVIVE®, helping restore performance and extend battery life.

Autocraft integrates the Ansomat Operator Guidance System across several use cases:

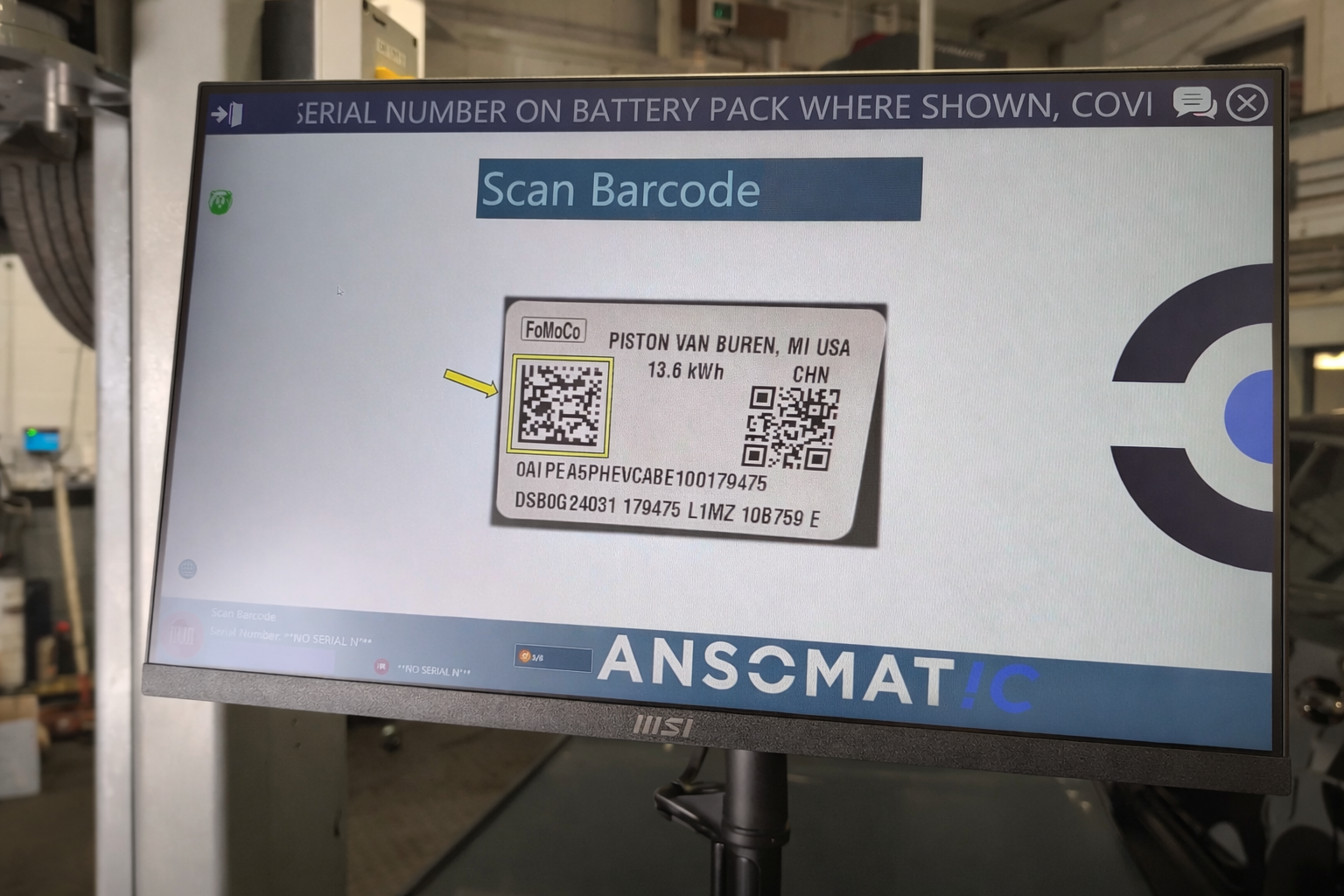

The system delivers digital, step-by-step work instructions, providing full quality assurance and traceability throughout every repair and remanufacturing operation.

Unresolved or misdiagnosed EV battery faults lead to high warranty costs, repeat repairs, and reduced customer confidence. Many garages lack the specialist tools and safe procedures required to detect false battery failures, resulting in unnecessary full pack replacements or unresolved issues.

Autocraft’s EV-health testing and guided repair workflow begins by scanning each battery into the Autocraft Cloud platform. Technicians then select the correct test sequence, including initial diagnostics, functional testing, post-repair validation, cell balancing, or tap testing. Advanced, cell-level diagnostics are performed instead of relying solely on the vehicle’s BMS.

Throughout the process, Ansomat digital work instructions guide technicians step-by-step and communicate with Autocraft infrastructure via MQTT, ensuring safe, standardized execution. Each job concludes with a comprehensive battery health report, reducing unnecessary pack replacements and improving first-time-fix success.

A revolutionary EV battery service concept

Autocraft is redefining EV battery servicing with its REVIVE® mobile service van, a containerized, on-site solution capable of testing, repairing, and remanufacturing EV battery packs using the Ansomat Digital Guidance Platform.

These semi-permanent or fully mobile containerized units can be rapidly deployed at super-dealerships or vehicle recycling centres, allowing packs to be safely tested and discharged prior to dismantling or recycling. Modular by design, they are ideal for customers managing high volumes of failed EV batteries across multiple vehicle brands.

Ansomat Operator Guidance – precision with human flexibility

Ansomat enables the flexibility of a skilled human operator with the repeatability and accuracy of a machine. It integrates machine vision, DC tooling, and dynamic function processes to error-proof every operation for any variant product.

Universal compatibility and guaranteed quality

The platform is compatible with all EV battery packs, with every process fully digitized. Technicians receive real-time feedback and visual instructions projected directly onto the workstation, creating an intuitive, mistake-proof working environment.

This ensures consistent operational excellence and the highest quality outcomes, every battery, every time.