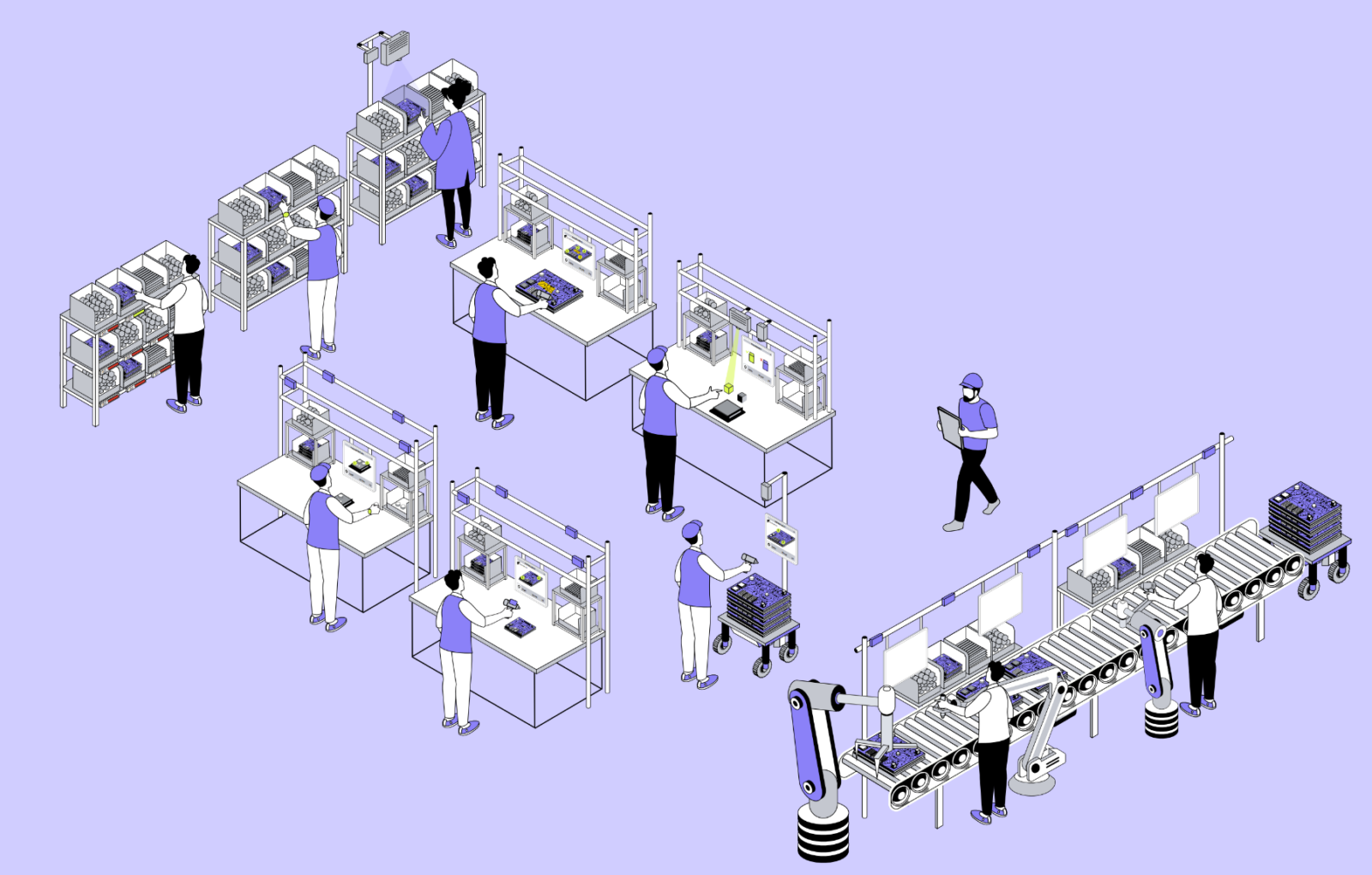

Operator guidance technology ensures that operators perform each task correctly the first time while streamlining manual processes for greater efficiency. It also provides full traceability, driving continuous improvement, quality assurance, and confidence on the shop floor.

Reduce scrap, rework and customer claims. Enable no-fault-forward production.

Support on-the-job learning.

Reduce the need for constant supervision.

Allow less experienced staff to perform complex tasks. Reduce reliance on memorization and lower operator stress.

We address a wide range of shop floor challenges. From workforce shortages and human errors to lack of transparency in manual operations and connecting machines without complicated PLC coding.

Eliminate paper-based processes and ensure every operator follows standardized, up-to-date work instructions.

Capture expert knowledge and standardize best practices before they’re lost.

Record every operator action automatically. Gain full traceability and insights for data driven decision making.

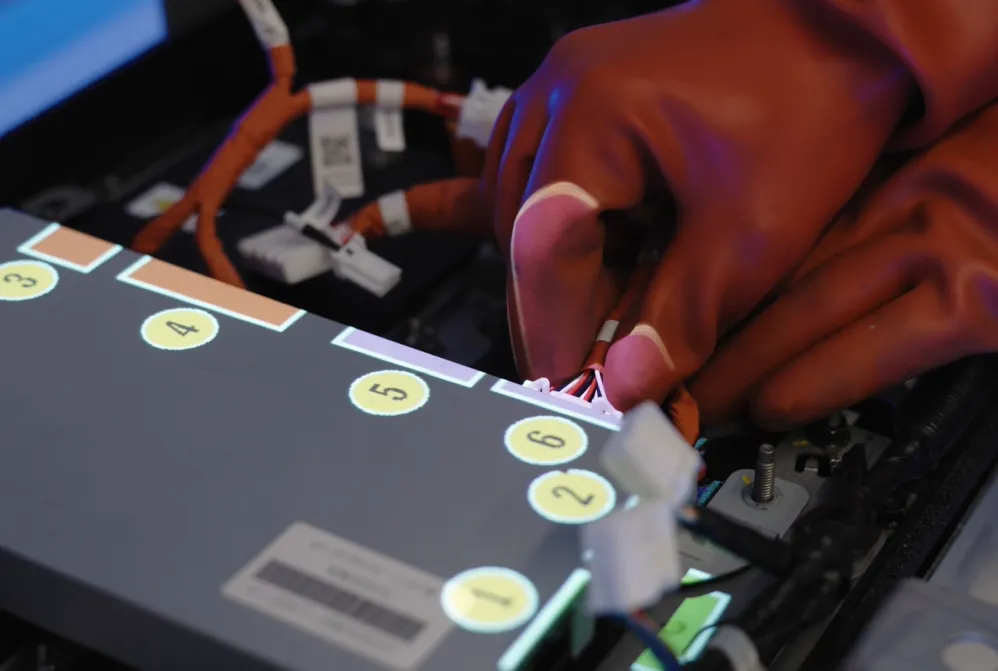

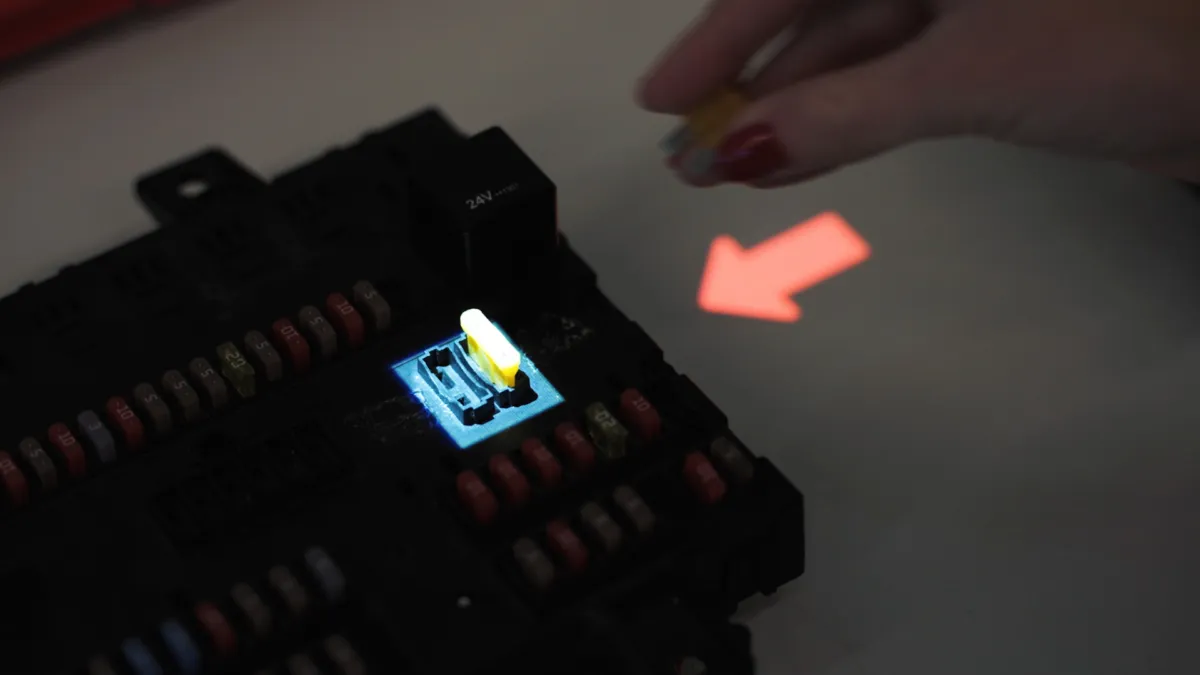

Prevent errors before they happen. Integrate smart tools and devices to stop defects at the source.

Deliver dynamic, personalized guidance based on worker skill levels or product variants.

Enable real-time data exchange between operators and machines through industry-standard protocols.

Our Operator Guidance technology is utilized throughout multiple shop floor activities, enabling seamless interaction between operators, tools, machines, robots, and production systems.

For over 30 years, Ansomat provides tightening tools and solutions for any assembly challenge.

NEW

Remotely, efficiently and at scale