How industrial AR evolved from lab curiosity into a core Industry 5.0 enabler

For many years, Augmented Reality was perceived as a futuristic concept that looked impressive in demonstrations but failed to create lasting value in real production environments, mainly because the technology was either too heavy, too expensive, or simply not usable for operators working eight-hour shifts under real industrial conditions.

Today, that situation has fundamentally changed.

Modern AR solutions are no longer experimental, no longer limited to pilot projects, and no longer dependent on awkward wearable devices that workers never fully accepted. Instead, AR has become a core productivity technology that supports operators in real time, eliminates human errors at the source, accelerates training, and allows manufacturers to standardize best practices across plants and continents.

The roots of Augmented Reality go back more than half a century to research laboratories, where early head-mounted displays were built mainly for academic research. These devices were large, unstable, and extremely expensive, which meant that they were never designed for real shopfloor usage but rather served as proof that digital information could be visually merged with the physical world.

At this stage, AR was an idea rather than a solution.

The first real industrial breakthrough came when Boeing engineers formally introduced the term “Augmented Reality” while working on systems to guide workers through highly complex aircraft wiring tasks. Instead of relying on paper manuals and memory, digital instructions were overlaid directly onto the physical structure of the aircraft, which immediately demonstrated that AR could reduce errors, shorten training times, and remove ambiguity from complicated assembly steps.

Even though these early solutions were limited to labs and pilot environments, they proved something essential: AR was not a gadget, but a productivity tool.

The next wave of AR came with the rise of smartphones and tablets powerful enough to support real-time 3D overlays and computer vision. For the first time, manufacturers could deploy AR at scale without massive hardware investments,

Use cases included:

Challenges:

Smart glasses such as Microsoft HoloLens, RealWear, and Vuzix aimed to solve the hands-free problem by placing information directly into the operator’s field of view.

Use cases:

Challenges:

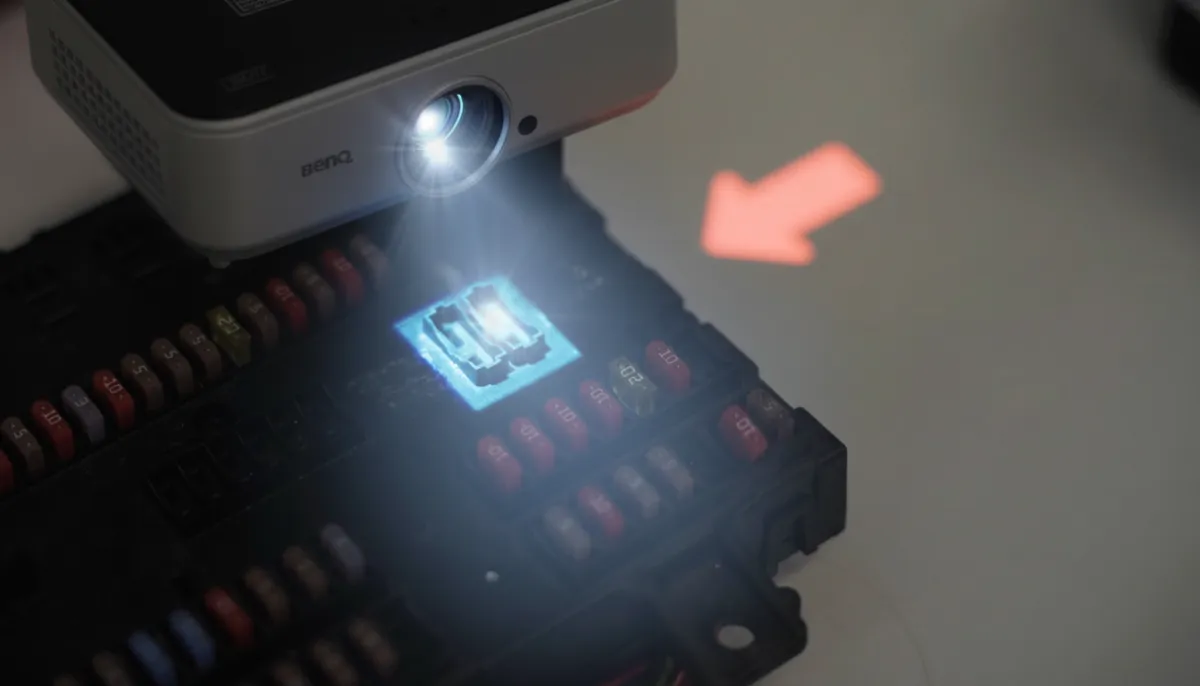

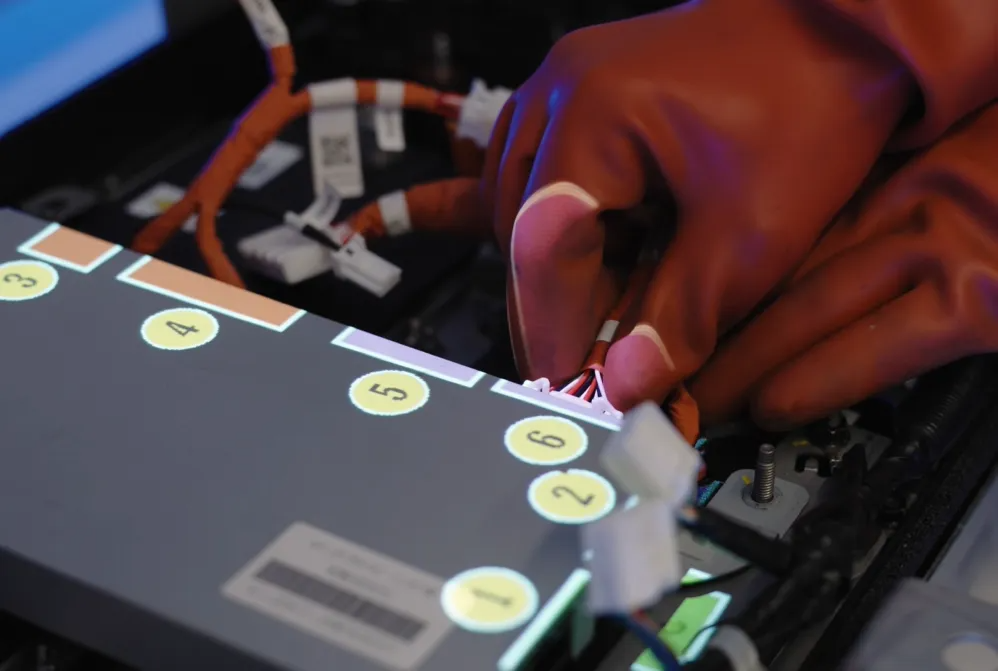

Projection-based AR, introduced a fundamentally different approach by removing all wearable hardware from the operator. Instead of asking workers to adapt to technology, the technology adapted to the workplace by projecting digital instructions directly onto parts through an AR projector, tools, and work surfaces using ordinary industrial projectors.

Applications:

This eliminated the biggest adoption barriers overnight: no devices to wear, no screens to hold, no cognitive overload.

With advances in AI-driven machine vision, AR systems are now able to track worker actions in real time, automatically verify correct execution of assembly steps, and integrate deeply with ERP, MES, and quality systems. This has turned AR into a true enterprise platform rather than a standalone tool.

Among all modalities, projection-based AR has consistently delivered the strongest return on investment, especially in assembly-heavy environments with high variant complexity.

The most important reason for its success is simple:

Operators don’t have to wear or hold anything.

No glasses.

No tablets.

No cognitive overload.

Benefits:

Especially in assembly, where two hands are always needed, projection-based AR eliminates the biggest adoption barriers.

Projection-based AR is ideal for fixed workstations. Some systems support moving objects, but layouts are less flexible than mobile AR.

Projectors must illuminate the relevant surfaces.

Make sure operators don’t block the projection cone during normal work.

Rule of thumb:

Bigger projection area = larger pixel size → lower accuracy

The more variants, the more important it becomes to automate instruction creation through:

if you don't have a lot of variants, avoid that AR is more seen as intruisive rather than helpful, if the work is very repeititve and operators do it day in and day out..

Define whether AR is intended for:

Quality control – Especially valuable in high-mix environments or where errors are likely.

AR visually presents each step instead of relying on memory.

Verify that there is sufficient overhead space to install projectors in the required positions.

Define how operators confirm that a task step is completed. This decision strongly influences usability, pace, and data quality.

Option 1: Time-based validation (Timer)

The instruction automatically advances after a fixed duration.

Option 2: Manual confirmation (Physical push button)

Operators confirm each step themselves.

Option 3: Automated validation (Machine Vision, 3D sensors, RTLS)

The system automatically detects correct completion and moves to the next step.

Introducing projection-based AR is not only a technology project, it is a behavioral and cultural change on the shopfloor.

Operators should not experience AR as something “imposed from above”.

This builds ownership instead of resistance.

Explain clearly:

Operators must understand that AR is there to support them, not to monitor or replace them.

Allow configuration levels so AR does not feel like a constraint for experienced staff.

Hands-on onboarding is essential:

Confidence comes from doing, not watching.

After go-live:

When operators see their feedback translated into system improvements, acceptance accelerates dramatically.

Bottom line:

The success of AR on the shopfloor depends far more on people adoption than on projection accuracy or software features. Technology enables change, but people make it real.

Modern AR operator guidance systems are increasingly integrated with machine vision to validate operator actions and automate workflows. With the rapid emergence of AI, these systems are becoming significantly smarter, allowing workflows to adapt dynamically based on what the system sees. As devices become lighter, less intrusive, and more intuitive, the likelihood of human error will continue to decrease while operator acceptance continues to rise.

AR platforms are evolving into technology-agnostic hubs that connect with a broad ecosystem of tools such as RTLS (real-time location systems), RFID, smart sensors, machine data streams, and torque tools. Rather than acting as a standalone application, AR is becoming the central orchestration layer for shopfloor actions, coordinating instruction design, execution, and real-time decision intelligence across the factory.

Manufacturing is moving toward a fully connected ecosystem where:

These systems are becoming seamlessly linked, creating a continuous digital thread that eliminates data silos and ensures that the right instructions are delivered at exactly the right moment.

AR is no longer just about visual guidance. It is becoming a powerful analytics engine that captures granular shopfloor behaviour, including:

AI-driven automation will increasingly generate instructions automatically, drastically reducing the administrative burden on process engineers so they can focus on high-value work rather than content creation.

Many platforms position AR as the heart of their solution, but in reality AR is simply one of many tools available to error-proof operator actions. In some environments, AR may not even be the best option - for example, when workstations are highly mobile, operators move constantly, or when projection-based AR becomes unnecessary once workers have fully internalized the process and simply switch it off.

The real objective is not AR adoption.

The objective is smarter manufacturing - and AR is only one of the instruments that makes it possible.

Project the correct bin directly onto the shelf.

Benefits:

AR displays the right instructions at the right time - especially powerful for high-mix production.

Benefits:

Every repair is different. AR dynamically displays instructions based on the detected issue.

Benefits:

Visual instructions reduce dependency on supervisors.

Benefits:

Visuals tell more than a thousand words.

Augmented Reality in manufacturing is no longer experimental.

It is a proven productivity, quality, and workforce-enablement technology - and projection-based AR is currently the most practical way to bring AR to the shopfloor at scale.

AR is not the destination.

It is the accelerator for the factories of the future.