Before starting any repair on aero boosters, technicians had to perform 5manual torque verifications to confirm wrench functionality. All checks were:

This created inefficiencies, introduced risk of human error, and made it hard to demonstrate compliance.

Digital Torque Validation

Ensure torque accuracy before every repair.

With Ansomat Operator guidance- new workflow verifies tool accuracy digitally, automatically linking torque measurements to the repair process.

Scan QR Code to Load the Correct Repair Sequence

Technicians scan a QR code on the component, instantly loading the appropriate repair digital work instructions.

Integrated Torque Testing Unit

Before starting any job, the system requires a torque test to verify digital torque wrench performance.

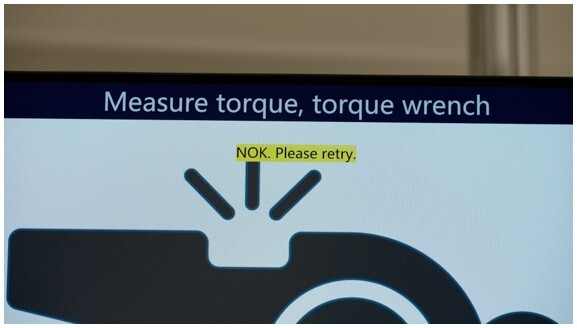

Automatic Out-of-Spec Detection

If the torque measurement falls outside specification, the system immediately triggers the relevant repair or calibration procedure.

Paperless Traceability

All measurements are stored digitally, ensuring full traceability without manual paperwork.

In-Process Picture Capture

Images with Companion App are taken during critical steps to further strengthen repair robustness and audit readiness.

With digital torque validation in place, MRO teams achieved higher confidence in their tools and their process:

In aerospace maintenance, a single incorrect torque value can have severe consequences. Digital torque validation ensures every wrench is proven accurate, every time, before work begins.

Discover how digital torque verification can safeguard quality and simplify compliance.