Many manufacturers are still running their operations on paper.

Even today, it is common to hear:

“We’ve always done it this way and it works fine.”

“We don’t make many mistakes.”

“We don’t really have quality issues.”

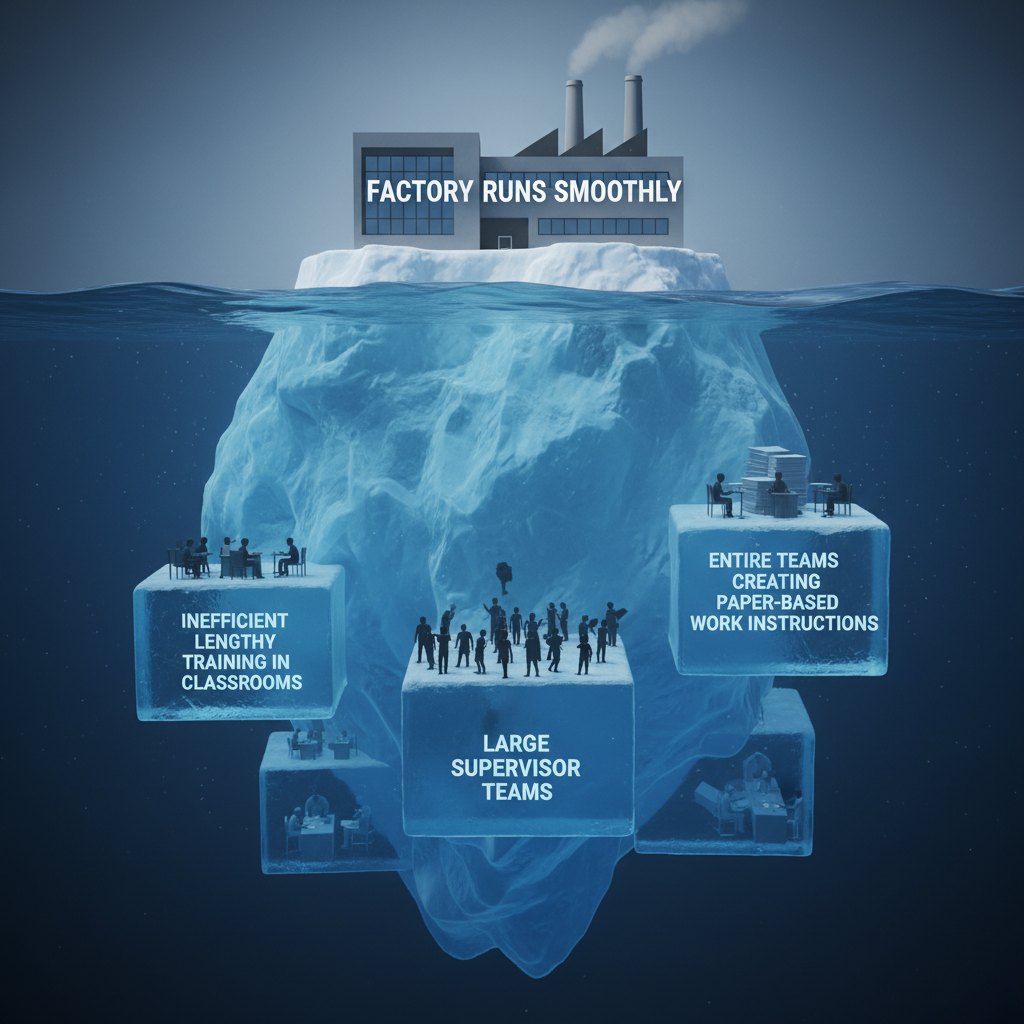

But what lies beneath the surface is far more dangerous.

Without traceability in how work instructions are created and how processes are executed, inefficiencies stay hidden, just like the submerged part of an iceberg. This is not a harmless blind spot; it is a structural risk that blocks learning, resilience, and long-term competitiveness.

1. Inefficient, Lengthy Training

Paper manuals slow down onboarding dramatically. New operators rely on text-heavy binders and tribal knowledge. Training takes longer than necessary, errors increase, and productivity drops during the critical first months.

2. Large Supervisor Teams

In many labor-intensive regions, manufacturers argue that labor is cheap, so they place supervisors next to every line.

But this adds variability on top of variability. Instead of standardizing work, the process becomes dependent on individuals, moods, experience levels, and communication quality.

3. Entire Teams Creating Paper Instructions

Some companies run full departments just to maintain SOPs:

This is expensive overhead with zero production value.

4. Separate Rework Flows

Paper systems rarely enable inline quality control. Instead, defective products are pushed into separate rework areas — creating parallel processes, extra handling, longer lead times, and higher scrap rates.

5. No Real Shopfloor Feedback

Operators make notes in the margins. Some leave unreadable handwriting. Others stop reporting problems and start working around them.

Paper blocks continuous improvement at the source.

6. Knowledge Lives in People’s Heads

In many factories, the most critical steps exist only in the minds of veteran workers.

When they leave, retire, or get sick, knowledge disappears — and performance drops instantly.

7. Zero Data, Zero Visibility

Paper provides no traceability.

No timestamps.

No error patterns.

No insight into where operators struggle.

Problems stay invisible, and improvement is based on gut feeling instead of facts.

Paper-based work instructions do not just cost money,

they block scale, consistency, and learning.

Most factories lose 6–12% of productivity every year due to hidden inefficiencies caused by paper, without ever seeing it on a financial statement.

1. Reduced labor hours spent on rework and scrap

Digital work instructions and AR work instructions prevents mistakes at the source instead of detecting them later. Operators are guided through the right sequence every time, dramatically reducing costly rework loops and material scrap.

2. Shorter onboarding and training time

New employees learn faster with visual, step-by-step digital work instructions, videos, and contextual help. This cuts weeks off ramp-up time and gets people productive earlier.

3. Less dependency on senior operators for daily support through knowledge preservation

When knowledge is embedded in the system, experienced workers are no longer the “human Google.” They stay focused on value-adding work instead of answering the same questions all day.

4. Prevention of errors you didn’t even know existed

With data and traceability of worker performance, hidden patterns emerge: which steps are skipped, where confusion occurs, and which products trigger the most mistakes, problems that paper never reveals.

5. One instruction set in all languages, improving diversity and inclusion

Digital work instruction platforms translate instructions instantly and use visuals instead of text-heavy manuals, enabling a diverse workforce to perform consistently regardless of native language.

6. Operators always using the latest version

Updates are deployed centrally and instantly. There is no risk of outdated binders or wrong revisions circulating on the shopfloor.

7. Streamlined processes with less waste

By standardizing best practices digitally, process variation is reduced. This leads to smoother flow, fewer interruptions, and less wasted motion, time, and material.

8. Decisions based on data, not assumptions

Every interaction generates insight: where operators struggle, how long steps take, and where defects originate. Improvements become evidence-driven instead of opinion-driven.

9. Less printing, storage, and document handling

No more constant reprinting, filing, and auditing of paper manuals. This removes direct costs and frees valuable floor and office space.

10. Lower hidden administrative overhead

Document control, version management, and audits become automated processes instead of manual chores, allowing support teams to focus on improvement instead of firefighting.

Paper-based work instructions may feel familiar, but familiarity is not efficiency. Beneath the surface, they quietly create rework, slow training, dependency on a few key people, and a total lack of visibility into what is really happening on the shopfloor.

Digital work instructions, enhanced with technologies like AR in manufacturing, replace guesswork with guidance, tribal knowledge with standardized best practice, and gut feeling with real data.

This is not about digitizing documents.

It is about building a manufacturing system that learns, scales, and improves every single day.

The factories that make this shift today will be the ones that outperform tomorrow.